Together with your fabrication (naked board) requirements documented, it’s now time to move on to an equally important stage – documenting the directions for element placement and remaining meeting. It is within the meeting stage where your bare board is delivered to life with all of the parts you specify in your Bill of Materials. This chapter will cowl what it is advisable know to have your board efficiently assembled and will cover meeting drawing necessities, adding notes, and placing cautionary markings. Your design documentation is arguably one among the most important features of your design process. Even the greatest PCB design will go to waste, if you are not capable of clearly talk design intent to your manufacturer. Along with your grasp drawing completed, you now have every little thing you have to get a naked board produced by your chosen fabricator. In the following chapter we will discover the last piece of the documentation puzzle for the ultimate meeting of your PCB. The required assembly documentation consists of plenty of assembly drawing templates that you’ll want to incorporate with your final design together with schematic prints and a finalized BOM. Along with your notes, these drawing templates will permit your manufacturer to clearly understand your design intent for remaining part placement and meeting. Also, be taught extra about how to reinforce Your Design Efficiency with Project Templates (WP). The schematic prints define your meant board part connections and are necessary to define and set up your required test points. During the final testing course of, your board tester may be able to find your take a look at factors on the physical PCB, but for larger readability they’ll make the most of your schematic prints to understand how these test factors connect to your community of circuitry. Figure 78 below shows a sample schematic with defined test points. The Bill of Materials will embody an in depth. Sourceable part listing that features all crucial part provider information. Providing a BOM to your producer with included part designators. Supplier info making certain your design can be manufactured with the suitable elements. The BOM is covered in depth later within the information. Cautionary markings are crucial for protected dealing with of your board. As a part of your assembly documentation, you will want to incorporate the electrostatic discharge markings shown in Figure ninety in case your board requires special dealing with due to static sensitivity. In addition to the symbols above, the notes in the desk beneath should be positioned above or as near the title bar as attainable. Assembly drawings, like fabrication drawings, require their own set of notes. These notes include data concerning the merging of the board with its components, together with assembly standards, dealing with instructions and solder specifications. There’s no such thing as too much element in your assembly documentation. If you assume your manufacturer must know one thing about a specific component’s placement or meeting necessities, make an observation for it. Draftsman is a classy yet straightforward to use drawing tool that is integrated inside Altium Designer, for the creation of fabrication and meeting drawings. Should you have almost any issues concerning exactly where along with how to make use of Pcb Assembly Cost, you can call us in our own web-site. Draftsman is a constructed-in extension that can be installed or removed manually by going to the Extensions and Updates web page. You’ll be able to entry the Extensions and Updates web page by clicking on the user icon on the highest proper of the Altium Designer window.

#1 PCB Manufacturing & Fabrication Company USA

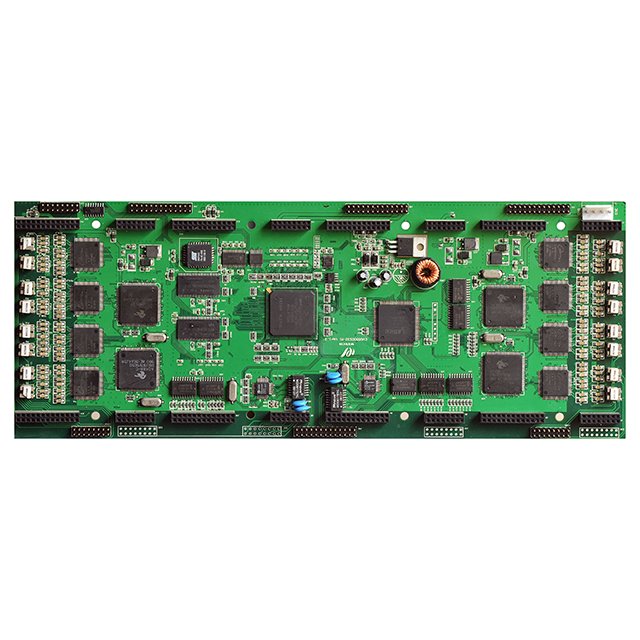

1 for Prime quality PCB Fabrication Services. Trusted by hundreds of PCB assembly, design & engineering firms. Quick turn, fast, and rapid PCBs. We concentrate on Quick flip PCB companies with an trade leading turnaround time as fast as 24 hours. When your company wants fast and rapid PCB prototyping, you may count on Custom Circuit Boards to deliver high quality printed circuit boards on time with competitive pricing. Perfect for testing or one-offs, utilize our entry-degree prototype PCB services with as much as 500 boards completed in a number of days. With our extensive prototype PCB fabrication capabilities, we are assured that we are going to exceed your company’s expectations for all of your easy to advanced PCB prototype requirements. We offer production amount PCBs at competitive go-to-market pricing with no NRE minimums or contracts. We now have the capabilities to manufacture your manufacturing printed circuit boards in-home at our Phoenix, AZ USA facility or in one in every of our offshore facilities. We’ve got the capabilities to manufacture 1 to 24 layered printed circuit boards. Our maximum board measurement for multilayer PCBs is 16″x26″ and PCB the usual PCB manufacturing turnaround time relies on the complexity and quantity of the boards wanted. As a leading PCB manufacturer in the USA, we construct naked boards starting from simple double-sided PCBs to class three extremely complex, mission important, multilayer aerospace and military (ITAR) PCBs. The right way to get a PCB quote Online. Fill out our Online PCB quote kind along with your PCB specifications or e mail them to us straight. One in all our account representatives will review your PCB necessities. Provide you with an accurate formal quote. Our company’s story. We started Custom Circuit Boards because we were tired of the poor customer service. Board high quality from other PCB corporations in the industry. We knew that we might do higher. Now, each day we do our greatest to exceed our buyer’s expectations by offering exceptional personal customer service and competitively priced excessive-quality printed circuit boards which can be delivered on time. We stay up for earning your production. Quick turn prototype PCB fabrication business. Testimonials and reviews. If you have any inquiries pertaining to where and how to use pcb guide, you can contact us at our own website. I’ve been utilizing Custom Circuit Boards as a PCB supplier for a few 12 months now. Have referred them to all of my colleagues. They have fabricated circuit boards which can be intended for frequencies from 1 GHz to six GHz dealing with RF powers of 10 Watts to 1000 Watts and their quality is great. The customer service, response instances, and services provided are wonderful and allow us to turn a new design in as little as three days which allows us to answer the quickly changing calls for of our prospects! You could have exceeded your opponents in the standard of the product. The way in which wherein the service was delivered. I just wished to drop you a line. Say thanks for your service Custom Circuit Boards! Everything turned out great, the PCBs worked high-quality on the primary prototype, and your service was just what we had hoped for. Quality work in a superb time-frame. I obtained into lab right this moment. The boards had been there. I just wished to say thank you for your entire help in getting these boards completed. Trusted by these companies. Example printed circuit boards manufactured by us. Now we have the PCB manufacturing capabilities to build easy double-sided boards to complex multilayer PCBs. 6 layer PCB with high temp FR-4, .062 thick, green mask, white legend, and ENIG finish. 2 layer board built on Rogers 4360 material, .031 thick, blue mask, and omikron end. 6 layer PCB on Isola 370HR materials, .062 thick, red mask, white legend, and onerous gold finish. 2 layer board on FR-4 material, .062 thick, inexperienced mask, white legend, and HAL finish. 4 layer PCB on Rogers 3010 material, .025 thick, inexperienced mask, printed circuit board white legend, and ENIG end. 2 layer board on Isola 370HR materials, .062 thick, white mask, black legend, and HAL end. We also have the capabilities to manufacture bare boards with different PCB supplies like Grace FR406, ISOLA FR408, Arlon, Nelco, Metal Core, and extra. Please contact us for extra data.

PCB Recycling – Disposal Of Scrap Printed Circuit Boards

Scrap PCB disposal & recycling services. Your organization’s outdate or non working, un-repairable or discarded PCB’s accommodates heavy metals and may comprise treasured metals corresponding to gold, palladium, silver, copper and totally different hazardous materials, these shall not be disposed of in a landfill. Most printed circuit boards are ENIG Electroless nickel immersion gold in different quantities of gold. We at B.W. Recycling, Inc, present circuit boards recycling options for most sorts of circuit boards, equivalent to telecommunications circuit playing cards, community communication boards, circuit packs, cell sites, Computer Pc boards (Pc mother boards and inside boards) as well as boards from laptops notebooks and tablets, we additionally take naked boards that means unpopulated boards. Usually we are ready pay for the boards by the lb, we additionally provide a certificate of recycling which certifies correct disposal of the PCB. We pay one of the best worth since we are the actual refinery. We also buy all sorts of printed circuit boards from cell phones and smart phones for recycling. We’re all the time prepared to purchase all sorts of populated PCB’s and plain (unpopulated) PCB’s, we decide up nationwide, when you’ve got green boards or any other digital scrap, we will likely be glad to have the possibility to recycle it for you, please contact us or just fill out the fast form on the best and we are going to contact you shortly with all of the information you want about our recycling program. There are numerous kinds of printed circuit boards with totally different treasured metals contents, some boards could contain more silver, some include extra gold, another solely comprise copper, with our experience we might be able to estimate the quantities of the precious metals we’d recuperate from the boards by looking at it, but there isn’t a set market value for all circuit boards. Some circuit boards might incorporates sure parameters or info that is required to be confidential, we at B.W. Recycling, Inc provide full destruction for the printed circuit boards based on ITAR rules upon request. More information about PCB recycling. In electronics, printed circuit boards, or PCB, also known as green boards, they are used to mechanically help and electrically connect electronic components utilizing conductive pathways, or traces, etched from copper sheets laminated onto a non-conductive substrate. Alternative names are printed wiring board (PWB), and etched wiring board. Populating the board with electronic parts forms a printed circuit assembly (PCA), also called a printed circuit board meeting (PCBA), this expertise is taken into account to be low value. In the recycling process of these boards we’re able to get well up to 99% of the treasured metals used to make the board, we’re the precise recyclers and most of the process is done in our plant, which allows us to pay high prices for your PCB’s as well as allow you to with a correct disposal solution for your scrap PCB’s. We do not buy or take scrap printed circuit boards out of Tv’s or Cathode Ray Tube monitors. If you cherished this report and you would like to receive a lot more data regarding pcb assembly (he said) kindly visit our own web page. We don’t buy PCB’s out of stereo’s, VCR’s or another boards from shopper electronics.

PCB Assembly – Manufacturing Services In USA

Printed circuit board meeting (PCBA) is a term used to depict a complete circuit board that features varied electronic elements for specific features. These elements are commonly assembled or soldered to a printed circuit board by way of a series of steps and procedures. This course of is leads to the formation of the printed circuit board assembly or printed circuit assembly (PCA). At Twisted Traces, we’ve a huge expertise and experience in offering printed circuit board meeting services to our customers. We guarantee the quality of services, along with aggressive costs and quickest turnaround times. We provide full turnkey and partial turnkey meeting services to our clients relying on their necessities. We consider our following PCB manufacturing and meeting capabilities have immensely contributed to our development as one of many leading PCB assembly service suppliers in the US. Specializing in PCB manufacturing and meeting, we now have had the privilege of serving purchasers across industries. Instant Online Quote: The Twisted Traces on-line calculator pcb assembly buying guide enables you to acquire a free PCBA quote in minutes. The price you see on the calculator will show you how to understand how much you need to pay at the tip of the assembly. Also, it will provide help to gain an understanding of the price rising components. Quick Turn PCB Assembly: We assure quick flip PCB assembly providers. We can provide turnkey PCB assemblies in 10-sixteen days. This consists of the time from designing to meeting to transport. Prototype, Small and Bulk Volume: Over the years, we have invested in applied sciences and sources, which permit us to satisfy PCB quantity requirements easily. We can present a single piece of assembled PCB or as much as 10,000 PCBs anytime. These PCBs are processed by our dedicated assembly strains. 100% Quality Guarantee: We guarantee a 100% high quality assure. We use only excessive-high quality parts throughout PCB manufacturing and assembly, which allows us to stand by our dedication of providing only quality-pushed merchandise. All products endure stringent testing at each section of manufacturing to avoid errors and threat of failures. If you have any inquiries pertaining to where and the best ways to make use of pcb assembly buying guide, you can call us at our own web site. World-Class Customer support: Being one of the trusted circuit board meeting companies suppliers in the US, we understand the importance of customer satisfaction. It doesn’t matter whether you’re inserting an enormous or small order, you may be working with a devoted customer support supervisor. Every subject will likely be communicated to you through the PCB manufacturing. Assembly process to maintain you aware of the challenges in the development. This also allows us to guarantee transparency in the PCB assembly and manufacturing course of. Being a leading PCB manufacturing and assembly services provider in the US, we provide PCBs in numerous designs and specifications. Twisted Traces understands the vital role performed by these PCBs in numerous functions. We have been providing prompt services to our shoppers across varied industries for a very long time now. It doesn’t matter, whether it’s a regular PCB or a complex design, we guarantee the fastest turnaround times and competitive costs.

It doesn’t matter, whether it’s a regular PCB or a complex design, we guarantee the fastest turnaround times and competitive costs.

The Basics Of A Printed Circuit Board: How Does A Circuit Board Work?

For all the wonders of electricity, it’s hard to forget that it takes something very bodily to make the “magic” occur. That factor is printed circuit boards (PCBs), which have long been the foundation of electrical engineering. PCBs are the “brain” and the spine of any electrically-powered system or kind. Regardless of its size, no electrically-powered gadget will work with out a PCB of some sort. Whether it’s a cellular phone, a distant control, one thing as sophisticated as a computer, or pcb assembly so simple as a child’s toy, a PCB offers the connectivity between all the components of a system. In consequence, the system will operate because it ought to. In this text, we are going to talk about the fundamentals of PCBS and explain how does a circuit board work. A printed circuit board is fabricated from non-conductive materials with copper layers overlayed. Electrical components are soldered onto the PCB by means of either wave soldering or selective soldering. A conformal coating is then added to protect the floor and safe its longevity. PCBs are the inspiration of electronic gadgets resembling computers, cellular gadgets, and navy know-how. There are a number of different types of PCBs to select from depending on the application. PCBs in one kind or another have been round for many years. Before PCBs were developed, circuits were wired on a chasse which was usually a steel body on a wooden backside. In the late nineteen thirties, an Australian engineer invented a printed circuit as part of a radio set and revolutionized the business. Fortunately, with the necessity for every part to change into smaller and smaller, as well as more environment friendly ways to energy these programs, PCBs grew to become not only extra integral in and of themselves, but due to the Internet, PCB board they grew to become more linked to all the pieces else. The results of all this has been not solely developments in the design of higher and smaller PCBs, higher connectivity with extra gadgets that had been far past their capabilities only some years in the past, with issues comparable to cellular apps, wearable units, and way more. How Does A Circuit Board Work? PCBs are deceptively easy on the subject of their construction. But are amazingly complicated with regards to the multitude that they allow us to accomplish in all of our electronic wonders. Regardless of how easy or advanced a gadget may be, a PCB of some kind is involved in channeling the electricity that’s drawn into the system to accomplish its supposed goal. It really is that straightforward. It’s a marvel when you think about that with only a few layers of resin and some channels of solder that permit electricity to journey via the totally different components of a board, small miracles occur that could not have been accomplished just a few years ago. But not solely do PCBs channel power, however they support the mechanics of the device itself. It’s because PCBs ship electrical impulses where they should go. Additionally they supply a help construction for all the components to hold quick to. It solely takes a quick look at a computer. Its internal apparatus to see this clearly. With all of this help offered by a PCB, it’s not onerous to see how PCBs are thought-about the brains of a chunk of gear. Without the PCB, a bit of digital gear quite merely wouldn’t work. PCBs are deceptively simple for other causes as properly. Although their design is simple, their creative course of is kind of advanced, beginning with a designer, creation of electronic design automation (EDA) software program, manufacturing, assembly, and testing. It’s at this level that an excellent circuit designer could be worth his or her weight in gold. They’ve the potential of creating a PCB that can maximize your specific technological needs. They will even be sure that that you have the assist you must excel in your market. Not enable your PCBs to develop into the weakest hyperlink in your product. A nicely-designed PCB will even be straightforward to troubleshoot when there may be a problem along with your gear. Once a file with the design is created the manufacture can be started. If you have any thoughts regarding where and how to use PCB board (find more info), you can speak to us at our own web site. In this course of, the actual bodily parameters of the PCB can be determined and maximized to be able to lead to a product with minimal issues and most advantages. During this course of, each attainable output is thoroughly tested to make it possible for it really works as it was intended to. With the testing methods available today there’s literally no way an side of a PCB is not going to be examined. This will be sure that there can be no failures in the way forward for the PCB that operates your product. If you’d prefer to study extra about how does a circuit board work and PCB Assembly companies for your small business, you’ll be able to look by our product/service choices. We try to supply the most full info at Hallmark Nameplate, to promote extra informed purchases for your online business.

Regardless of its size, no electrically-powered gadget will work with out a PCB of some sort. Whether it’s a cellular phone, a distant control, one thing as sophisticated as a computer, or pcb assembly so simple as a child’s toy, a PCB offers the connectivity between all the components of a system. In consequence, the system will operate because it ought to. In this text, we are going to talk about the fundamentals of PCBS and explain how does a circuit board work. A printed circuit board is fabricated from non-conductive materials with copper layers overlayed. Electrical components are soldered onto the PCB by means of either wave soldering or selective soldering. A conformal coating is then added to protect the floor and safe its longevity. PCBs are the inspiration of electronic gadgets resembling computers, cellular gadgets, and navy know-how. There are a number of different types of PCBs to select from depending on the application. PCBs in one kind or another have been round for many years. Before PCBs were developed, circuits were wired on a chasse which was usually a steel body on a wooden backside. In the late nineteen thirties, an Australian engineer invented a printed circuit as part of a radio set and revolutionized the business. Fortunately, with the necessity for every part to change into smaller and smaller, as well as more environment friendly ways to energy these programs, PCBs grew to become not only extra integral in and of themselves, but due to the Internet, PCB board they grew to become more linked to all the pieces else. The results of all this has been not solely developments in the design of higher and smaller PCBs, higher connectivity with extra gadgets that had been far past their capabilities only some years in the past, with issues comparable to cellular apps, wearable units, and way more. How Does A Circuit Board Work? PCBs are deceptively easy on the subject of their construction. But are amazingly complicated with regards to the multitude that they allow us to accomplish in all of our electronic wonders. Regardless of how easy or advanced a gadget may be, a PCB of some kind is involved in channeling the electricity that’s drawn into the system to accomplish its supposed goal. It really is that straightforward. It’s a marvel when you think about that with only a few layers of resin and some channels of solder that permit electricity to journey via the totally different components of a board, small miracles occur that could not have been accomplished just a few years ago. But not solely do PCBs channel power, however they support the mechanics of the device itself. It’s because PCBs ship electrical impulses where they should go. Additionally they supply a help construction for all the components to hold quick to. It solely takes a quick look at a computer. Its internal apparatus to see this clearly. With all of this help offered by a PCB, it’s not onerous to see how PCBs are thought-about the brains of a chunk of gear. Without the PCB, a bit of digital gear quite merely wouldn’t work. PCBs are deceptively simple for other causes as properly. Although their design is simple, their creative course of is kind of advanced, beginning with a designer, creation of electronic design automation (EDA) software program, manufacturing, assembly, and testing. It’s at this level that an excellent circuit designer could be worth his or her weight in gold. They’ve the potential of creating a PCB that can maximize your specific technological needs. They will even be sure that that you have the assist you must excel in your market. Not enable your PCBs to develop into the weakest hyperlink in your product. A nicely-designed PCB will even be straightforward to troubleshoot when there may be a problem along with your gear. Once a file with the design is created the manufacture can be started. If you have any thoughts regarding where and how to use PCB board (find more info), you can speak to us at our own web site. In this course of, the actual bodily parameters of the PCB can be determined and maximized to be able to lead to a product with minimal issues and most advantages. During this course of, each attainable output is thoroughly tested to make it possible for it really works as it was intended to. With the testing methods available today there’s literally no way an side of a PCB is not going to be examined. This will be sure that there can be no failures in the way forward for the PCB that operates your product. If you’d prefer to study extra about how does a circuit board work and PCB Assembly companies for your small business, you’ll be able to look by our product/service choices. We try to supply the most full info at Hallmark Nameplate, to promote extra informed purchases for your online business.

Kano’s Latest Coding Kit Is A Star Wars-themed Motion Sensor

Back in January, Kano revealed that it was working with Disney on a Star Wars-themed coding equipment. It’s taken a while, but at the moment we finally know what the company — greatest identified for its colorful Raspberry Pi computers — has been cooking up: Star Wars The Force Coding Kit. The Bluetooth-enabled movement sensor includes a circular case, printed circuit board with 9 LEDs, and two tops that include Rebel Alliance and Galactic Empire iconography. Once assembled, it can be used to regulate lightsabers, Porgs and different Star Wars paraphernalia in a companion app that’s compatible with Windows 10 PCs, Macs, iPads and Amazon Fire HD 10 tablets. If you want to force push a Tie Fighter, although, you’ll need to assemble some code first. Like earlier Kano products, the bulk of your time can be spent tweaking puzzle-like programming pieces inside the app. These blocks dictate what is shown on display screen and, more importantly, how they react to your hand movements in the true world. One challenge, as an example, PCB would possibly train you methods to wield a lightsaber, while another reveals you the way to boost an X-wing like Luke did within the Empire Strikes Back. Once you’ve accomplished a lesson, you’ll be free to tweak the challenge or create a new one from scratch. Custom initiatives may be shared on Star Wars Kano World, a easy however practical social network that permits you to view, pcba download and rework different individuals’s creations. The corporate has additionally promised to support the package with further challenges put up-launch. If you’re involved, Star Wars The Force Coding Kit will launch on October 4th for $79.99/£79.99. It is going to be bought by means of Kano’s webpage and choose retailers within the US, UK and Canada, including Amazon, Target and Best Buy. It is not the primary time Kano has collaborated with a big brand. Last yr, Kano launched a physical wand that lets you create and manipulate iconic spells from the Harry Potter universe. Here’s more info in regards to PCB (transtats.bts.gov) have a look at our own internet site. The company has teamed up with Microsoft, too, pcb assembly on a Windows 10 laptop that is scheduled to ship subsequent month. Chief executive Alex Klein is adamant, though, that Kano hasn’t given up on its crowdfunded trio of bodily computing kits. The Kickstarter ended in September 2016, however to date solely one of many products — a charming and instructional programmable gentle board — has reached backers and store shelves. The corporate is offering refunds, at the very least, to anyone who doesn’t need to wait any longer for the speaker or digicam kit. All products recommended by Engadget are selected by our editorial staff, independent of our mother or father firm. A few of our stories include affiliate links. If you purchase something by means of one of these hyperlinks, we might earn an affiliate commission.