Malala Yousafzai has shocked her millions of supporters around the world by getting married in a small, shifting ceremony at her Birmingham residence. The youngest ever winner of the Nobel Peace Prize, now 24, spoke of her excitement for the ‘journey forward’ after tying the knot with Pakistani cricket coach Asser Malik in a relationship that had been saved secret from the wider world. The completely happy day comes more than 9 years after she survived being shot within the face by the Taliban after she campaigned for girls to go to highschool. Malala shared candy photographs from the Nikkah – Islamic marriage ceremony – where she wore a fantastic pink bridal outfit. She is seen smiling next to her new husband, who wore a matching pink tie, in adorable outside snaps. While one other picture shows Malala touching her hair as Asser signed the wedding contract. Malala captioned the images: ‘Today marks a treasured day in my life. Asser and that i tied the knot to be partners for all times. We celebrated a small nikkah ceremony at house in Birmingham with our families. Please ship us your prayers. Malala and her new husband Printed Circuit Board gaze into each others eyes within the gorgeous photographs from their Nikkah: ‘Today marks a treasured day in my life. Malala and her new husband Asser Malik pose for a picture on their wedding ceremony day along with her father Ziauddin Yousafzai and mother Toor Pekai Yousafzai. If you have virtually any issues about where in addition to tips on how to use printed circuit board (you can try here), it is possible to email us at our own internet site. Malala and Asser’s relationship had been kept secret from the wider world. The one trace of the blossoming romance came in July when Asser posted a birthday message to his future spouse which read ‘Happy Birthday to probably the most amazing Malala’ alongside a photograph of the couple standing subsequent to each other. It is unknown how long Malala and Mr Malik have been relationship however in June 2019, they had been pictured along with a bunch of associates watching England play Pakistan at Edgbaston. News of her wedding took social media by surprise, however tens of hundreds of well-wishers including Jemima Khan, Greta Thunberg and Canadian PM Justin Trudeau sent messages of congratulations to the blissful couple. Mr Malik is understood to be in his early thirties. Was last year appointed excessive efficiency supervisor of the Pakistan Cricket Board (PCB). He had previously labored as an operations manager for Pakistan Super League (PSL) franchise Multan Sultans. Mr Malik additionally runs an newbie league franchise called Last Man Stands in Pakistan, which he has described as an try and ‘revive grassroots cricket in Pakistan in an organised and structured manner’. He graduated from the Lahore University of Management Sciences in 2012 with a degree in economics and political science. Other roles listed on his LinkedIn web page embody sixteen months working at Coca-Cola Beverages Pakistan Limited, and 14 months as a managing director at a participant management company. As well as cricket he is a identified supporter of Newcastle United fc. Malala and Asser Malik pictured with pals in June 2019, watching the England versus Pakistan cricket recreation at Edgbaston. It’s unclear where the couple will make their residence. Malala has lived in Birmingham since 2014 whereas her husband’s job relies in Lahore, Pakistan. Within the run as much as the surprise wedding ceremony, he has been seemingly preoccupied on Twitter with the progress of the Pakistan cricket group which has reached the semi-finals of the T20 World Cup being played within the United Arab Emirates. Earlier this year, Malala’s father Ziauddin Yousafzai said he would permit her to choose her personal accomplice. Her parents had what has been described as an ‘an organized love marriage’. COP26’s largest delegation? The fossil gas business! Malala has previously expressed doubts about whether or not she would ever marry. In June she informed Vogue: ‘I still don’t understand why folks need to get married. If you wish to have a person in your life, why do you have to sign marriage papers, why can’t it just be a partnership? At the age of 15 Malala survived being shot in the pinnacle by a Taliban gunman after campaigning for girls to be educated. She has since turn into a world icon for ladies’s rights. In an unique interview with MailOnline 9 months ago, Mr Yousafzai, 51, said his daughter was totally unbiased and will create the life she desires.

Malala shared candy photographs from the Nikkah – Islamic marriage ceremony – where she wore a fantastic pink bridal outfit. She is seen smiling next to her new husband, who wore a matching pink tie, in adorable outside snaps. While one other picture shows Malala touching her hair as Asser signed the wedding contract. Malala captioned the images: ‘Today marks a treasured day in my life. Asser and that i tied the knot to be partners for all times. We celebrated a small nikkah ceremony at house in Birmingham with our families. Please ship us your prayers. Malala and her new husband Printed Circuit Board gaze into each others eyes within the gorgeous photographs from their Nikkah: ‘Today marks a treasured day in my life. Malala and her new husband Asser Malik pose for a picture on their wedding ceremony day along with her father Ziauddin Yousafzai and mother Toor Pekai Yousafzai. If you have virtually any issues about where in addition to tips on how to use printed circuit board (you can try here), it is possible to email us at our own internet site. Malala and Asser’s relationship had been kept secret from the wider world. The one trace of the blossoming romance came in July when Asser posted a birthday message to his future spouse which read ‘Happy Birthday to probably the most amazing Malala’ alongside a photograph of the couple standing subsequent to each other. It is unknown how long Malala and Mr Malik have been relationship however in June 2019, they had been pictured along with a bunch of associates watching England play Pakistan at Edgbaston. News of her wedding took social media by surprise, however tens of hundreds of well-wishers including Jemima Khan, Greta Thunberg and Canadian PM Justin Trudeau sent messages of congratulations to the blissful couple. Mr Malik is understood to be in his early thirties. Was last year appointed excessive efficiency supervisor of the Pakistan Cricket Board (PCB). He had previously labored as an operations manager for Pakistan Super League (PSL) franchise Multan Sultans. Mr Malik additionally runs an newbie league franchise called Last Man Stands in Pakistan, which he has described as an try and ‘revive grassroots cricket in Pakistan in an organised and structured manner’. He graduated from the Lahore University of Management Sciences in 2012 with a degree in economics and political science. Other roles listed on his LinkedIn web page embody sixteen months working at Coca-Cola Beverages Pakistan Limited, and 14 months as a managing director at a participant management company. As well as cricket he is a identified supporter of Newcastle United fc. Malala and Asser Malik pictured with pals in June 2019, watching the England versus Pakistan cricket recreation at Edgbaston. It’s unclear where the couple will make their residence. Malala has lived in Birmingham since 2014 whereas her husband’s job relies in Lahore, Pakistan. Within the run as much as the surprise wedding ceremony, he has been seemingly preoccupied on Twitter with the progress of the Pakistan cricket group which has reached the semi-finals of the T20 World Cup being played within the United Arab Emirates. Earlier this year, Malala’s father Ziauddin Yousafzai said he would permit her to choose her personal accomplice. Her parents had what has been described as an ‘an organized love marriage’. COP26’s largest delegation? The fossil gas business! Malala has previously expressed doubts about whether or not she would ever marry. In June she informed Vogue: ‘I still don’t understand why folks need to get married. If you wish to have a person in your life, why do you have to sign marriage papers, why can’t it just be a partnership? At the age of 15 Malala survived being shot in the pinnacle by a Taliban gunman after campaigning for girls to be educated. She has since turn into a world icon for ladies’s rights. In an unique interview with MailOnline 9 months ago, Mr Yousafzai, 51, said his daughter was totally unbiased and will create the life she desires.

This Cute Def Con Badge Beckons You To Hack It

At earlier Def Cons I wrote concerning the unofficial badges. The tradition surrounding those pieces of technology. This yr I was determined to move previous my infatuation with blinking lights and colorful PCBs (printed circuit boards). Then I saw the Maneki Neko badge. It is the iconic beckoning cat (literally what “maneki-neko” means) with a transferring 3D-printed arm. Two 16-section LEDs that blink at you while it waves. Fine, you got me. Creators Sean McCabe and Daniel Samarin needed to do something a bit totally different for their badge this yr. Def Con badges with their lights, video games and insane puzzles are all spectacular, however with its 3D-printed waving cat paw, the Maneki Neko stood out from the pack.”Everyone loves cats!” McCabe mentioned. Should you have virtually any queries about wherever as well as the way to use PCB, Click at Ezproxy Cityu Edu,, it is possible to call us from our own web site. That realization led to the badge. It’s part whimsy and part ensuring they don’t lose their shirts whereas creating something fun. This is McCabe’s second badge. He built a small 3D-printed badge final yr, which was his first time prototyping a board. This 12 months’s badge offered for $eighty cash. For those who needed one, you had to follow the crew on Twitter and wait until it announced a “drop.” Unsurprisingly, it sold out. If you are enthusiastic about your individual, all just isn’t misplaced. McCabe and Samarin positioned everything you must make your individual on GitHub. McCabe said, “You may take the badge and do what you need with it. The board is on GitHub; they’ll take it and ship it to a fab” (fabrication facility). The truth that all of the code is on GitHub also implies that those who did purchase a badge at the yearly hacker conference can go home and tinker with it as a substitute of just throwing it in a drawer. From the appears of the badge, there’s little or no likelihood that is going to occur. As for subsequent yr, they plan on making another badge with moving parts and 3D printing. They have not solidified on something yet, however they want to proceed with the theme of building one thing that brings people joy put up-convention. All merchandise beneficial by Engadget are chosen by our editorial workforce, impartial of our parent firm. Some of our tales embrace affiliate hyperlinks. If you buy one thing by means of one of those hyperlinks, pcba we could earn an affiliate commission.

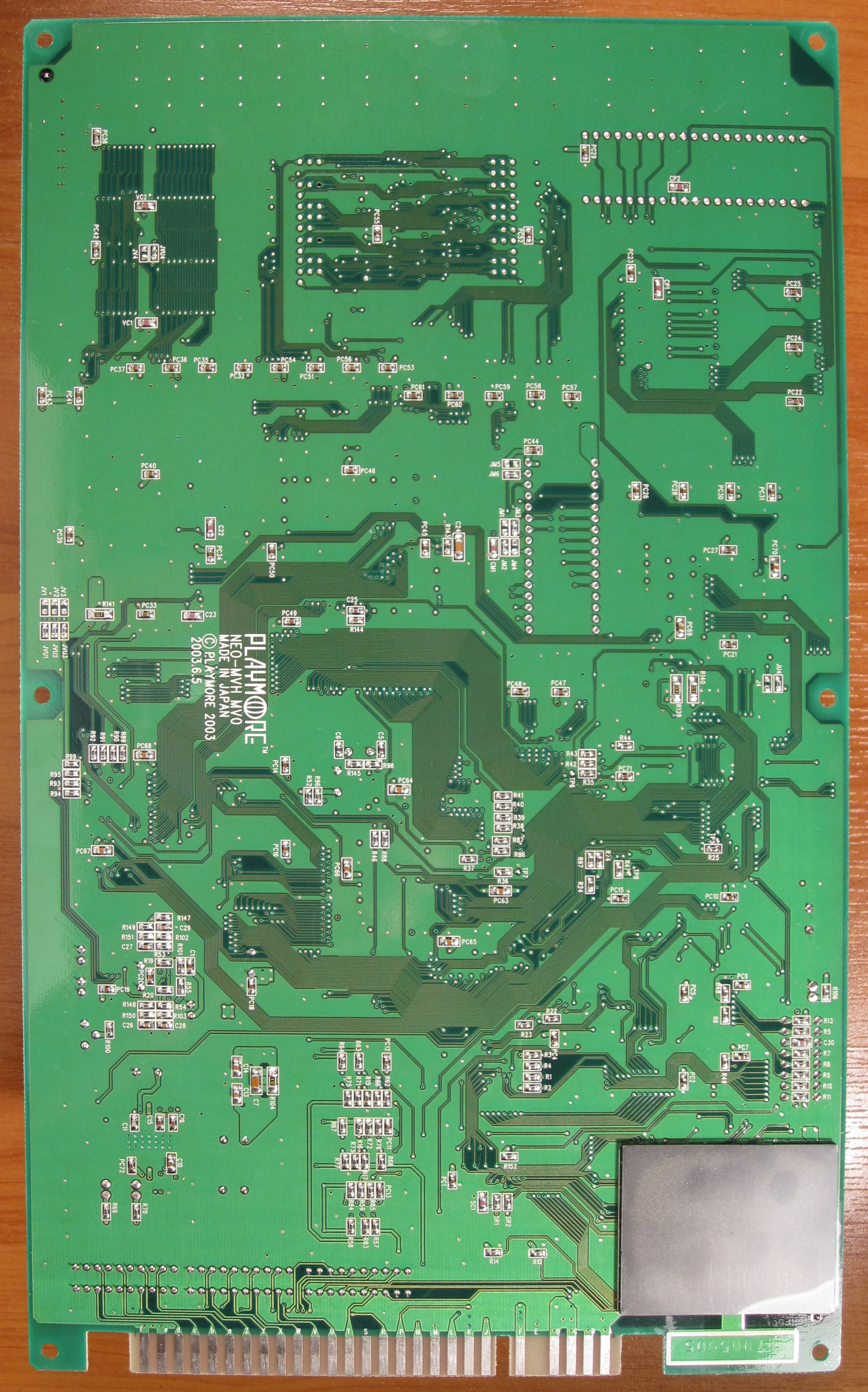

What To Pay Attention To When Using High-Speed PCB Vias

Via is likely one of the important elements of the multi-layer PCB circuit board, and the cost of drilling often accounts for 30% to 40% of the cost of a PCB board. Simply put, each hole on a PCB can be called a via. By way of course of, these vias are usually divided into three categories, specifically blind vias, buried vias, and via vias. Located on the highest and backside surfaces of a printed circuit board, it has a sure depth and is used for PCB buy the connection of the surface layer and PCBA (Files.fm) the underlying interior layer. The depth of the outlet often doesn’t exceed a sure ratio (diameter). Refers to the connection gap positioned on the inner layer of the printed circuit board, which does not prolong to the floor of the circuit board. The above two types of holes are located within the inner layer of the circuit board. Are completed by the by way of-gap forming process before lamination. During the formation of the via gap, a number of inside layers may be overlapped. This gap runs through the whole board. In the event you loved this article and you would like to receive more info regarding PCB buy i implore you to visit our web site. Can be used for inside interconnection or as a mounting gap for parts. Because the by-hole is less complicated to understand in the process and the fee is decrease, pcb assembly a lot of the printed circuit boards use it as an alternative of the opposite two sorts of by way of holes. The via holes talked about below are thought of as by way of holes except in any other case specified. From a design perspective, a through is primarily composed of two parts, one is the drill hole within the center, and the other is the pad space around the drill gap. The scale of those two components determines the size of the via. Obviously, in high-pace, excessive-density PCB design, it’s all the time hoped that the smaller the via gap, the better, so that more wiring space may be left on the board. In addition, the smaller the by way of hole, the smaller its own parasitic capacitance. However, the discount in gap dimension additionally brings a rise in cost, and the size of the by way of gap cannot be lowered indefinitely. It is limited by course of applied sciences resembling drilling and pcb assembly plating: the smaller the hole, the more drilling. The longer the hole takes, the easier it’s to deviate from the center; and when the depth of the hole exceeds 6 instances the diameter of the drilled gap, it isn’t assured that the hole wall can be uniformly plated with copper. With the development of laser drilling technology, the size of the drill gap can even become smaller and smaller. Generally, the through hole with a diameter of less than or equal to 6Mil known as a micro-gap. Micro vias are sometimes used in HDI (High-Density Interconnection) designs. Microvia technology allows vias to be straight punched on the pad (Via-in-pad), which vastly improves circuit performance and saves wiring space. Vias appear as discontinuous discontinuities in impedance on the transmission line, inflicting signal reflection. Generally, the equal impedance of the via is about 12% decrease than that of the transmission line.

Full & Partial Turnkey PCB Assembly Services

As an expert contract turnkey PCB assembly manufacturer with extensive experience in PCB fabrication, parts sourcing, design and meeting for electronics outsourcing firms or people. Our specialty ranges from prototype to high-quantity assembly on basis of full turnkey PCB assembly and partial turnkey PCB assembly. PCB board assemblies and dependable, trade-leading contract manufacturing services from China. Full turnkey PCB assembly requires clients to send their design recordsdata, whereas the contract manufacturer will present SMT stencil, PCB boards, and the parts required on BOM for the assembly. This means all the pieces right from components procurement to assembly is carried out by the PCB assembly manufacturer. The next are the important thing advantages of availing this PCB assembly service. Most manufacturers have strong relationships with components suppliers, which helps them supply the elements effectively at aggressive costs. The elements are largely procured in meeting pleasant packages, like minimize-tapes, or tape and reels to save price. A customer may be relaxed that every one procurement. Assembly is being handled by the producer. Because the name implies, in this type of PCB assembly, a customer sources some parts and components, and the rest is sourced by the producer. In this course of, the producer has to hunt approval from the customer on parts’ costs, their quality, and availability, before the precise meeting starts. The sort of meeting helps strike a good stability between kitted and turnkey. If you liked this post along with you would like to obtain more information about pcb assembly price generously check out the web site. A buyer provides costly elements similar to connectors, IC’s and etc., whereas the PCB assembler will supply the rest parts, which helps saving time for both sides. If a customer has constructed sturdy supply chain relationships then they’ll easily benefit in terms of prices by sourcing elements at cheaper rates. Assembly course of and preparations shall be much faster than the total turnkey assembly. With our PCB and meeting manufacturing amenities in Shenzhen, MADPCB serves prospects in quite a lot of industries, together with Industrial, Communications, Medical, Wearable Devices, IoT, Navigation System, Bio-robotics, Monitoring System, Aviation, LED Lighting and etc., due to our dedication to meet the customers’ specs, high quality, value considerations and on-time delivery. Every PCB assembly is manufactured in compliance to standards of ISO 9001, RoHS, IPC-A-600 and IPC-A-610, which additionally ensures the product -PCBs and PCBAs are completed in our SMT home meet environmental and regulatory requirements. All naked PCB boards are assembled to comply with IPC-A-610 requirements. All assembling technicians. Inspectors are with skilled experience. All PCB manufacturing handles by ourselves to comply with IPC Class II or III standards upon requirements. 100% electrical check on all bare Printed Circuit Boards by flying probe or fixture. 100% visible inspection after electronic PCB assembly completion. 100% practical check as per documented take a look at procedures (optionally available). 100% all PCBAs cleaning. Strict electronic static discharge (ESD) control. Files: please include all the layers (copper, solder mask, silkscreen, solder paste, define, thru-via hole, blind and buried by way of, micro-through, carbon ink printing, FPC stiffener, EMI film and and many others.). Bill of Materials (BOM) in Excel format. 7. It is highly fascinating to include columns to point whether or not the components are consigned by you, MADPCB provided or not populated. Centroid File: also known as choose and place file, or coordinates file. It should embrace element places, rotations and reference designators in .csv format. Assembly Drawings (Optional) if there are solder paste layer in your Gerber file zip folder. Assembly Notes, helpful for complex PCB and assembly manufacturing, often in .pdf format.

How Does A Printed Circuit Board Work?

Printed circuit boards are important for computers, but how does a printed circuit board work? This guide reveals the fundamentals of PCBs. Have you wondered what precisely goes into your phone or computer to make it work? A printed circuit board technology is what our complete modern world is based on. Since they go into all the pieces round us, you’re even worried about being hacked or spied on. A PCB is sort of a black field to most people-they don’t know how it works, and they’re afraid to have a look under the hood. We’re here to inform you it’s okay to look! So long as you don’t attempt to drill a hole in the board-keep studying to find out why. What Goes in. On a PCB? What’s a Printed Circuit Board? How Do Circuit Boards Work? What Goes in. On a PCB? First of all, we need to know what goes into it, right? A protracted listing, but obligatory, since there are so many different varieties, PCB corresponding to rigid, flex, and rigid-flex circuit boards. The different materials combine in numerous configurations to carry out a design objective. This may be heat dissipation, fast and correct transmission of electricity or any variety of different necessities. Some materials are extra durable than others however price-prohibitive. However, certain applications, PCB akin to navy use, require excessive-end materials for the manufacturing of the PCB. What is a Printed Circuit Board? A PCB is how our lives work today. It’s sometimes made of 1 to forty layers of substrate and copper foil “traces.” It’s much like an electrical grid for a metropolis, or even a avenue map. We often imagine them going into solely computers. But phones, TVs, cars, airplanes, clocks, and even your espresso pot is chock stuffed with PCBs. If we continue to think about a PCB board as a metropolis, it’s how city hall talks to the hearth division, and the central enterprise district hyperlinks to residential areas. The different elements of a computer, for example, just like the CPU, RAM, GPU, all want to speak to work by way of completely different tasks. The PCB is what connects them in a tightly wound internet of copper and fiberglass. Everything is so shut together in a pcb assembly, which regularly causes complications. Thermal administration and electromagnetic issues are the most important issues PCBs face. Professionals name this Electromagnetic Interference or EMI. Thermal management points and EMI typically cause early degradation of the board or of its means to function. For that reason, they use non-conductive materials in combination with copper in layers. The one layer you often see is the highest layer. For those who drill into a board to fit it right into a custom case, you would make it fully inoperable. Since you don’t see traces doesn’t mean there aren’t any on lower layers. How Do Circuit Boards Work? Circuit boards use a number of “tools” to carry out their designed duties. These parts act in a similar method to stop lights, parking tons, roundabouts, and different visitors management techniques. Capacitors store an electric charge. Act as a form of parking lot for electricity. Resistors do as they are saying. Provide resistance in a system. Imagine a yield signal or flashing yellow, which acts to typically gradual traffic and stop overloading a street or inflicting a collision. In a system without braking, some parts of the PCB (www.linkagogo.com) would overload with electricity or overheat as all the electrons attempt to enter it without delay. That heat additionally contributes to the catastrophic degradation of the system, even damage. Diodes are like one-means streets, and permit electricity to circulate in only one route as soon as passing via it. That means electricity can’t surge backward. Cause a see-noticed movement of electrons. This creates magnetic waves and heat, which as we all know aren’t any good for the system. Inductors can retailer electrical power as a magnetic field. Also, they forestall AC electricity from flowing while still allowing DC electricity to cross via. This permits for the transformation of electrical states on the very least. The components of the board (the chips) comprise the transistors, which do the calculations. The PCB acts because the roadway community to these places, and connects the electrical currents, as well as protect them from overload. As parts are set into the board and soldered on, they might contact just one layer. Or, they may contact many layers at different depths to succeed in components. This complexity makes it troublesome for humans to design by hand. Computers assist within the design by calculating finest pathways for traces. This is named CAD or Computer Assisted Design. Still, even with the help of computer systems failures occur. This blog publish can enable you be taught extra about why even a superb design on paper doesn’t translate right into a practical one. Although, if you’re a hobbyist who desires to interrupt into making your own PCB, don’t be afraid. There are actually a number of DIY processes for less complex methods. This features a “breadboard” circuit array often used for testing. This gives a wonderful learning expertise. Now that you understand how a printed circuit board works, and what it might probably do, don’t you are feeling higher? They’re all over the place around us, and essential for our method of life as we speak. Eventually, they’ll get smaller and extra advanced until a new technology replaces it. Just like the previous method of handbook tracing and uncovered wires and vacuum tubes had been changed. Then we’ll have a new black field to determine, though for now we now have what we’ve got and we’re completely happy about it! If this tech article tickled your transistor, we’ve received lots more for you to read! Review How Does a Printed Circuit Board Work? The basics of PCBs.

The basics of PCBs.

What’s Turnkey PCB Assembly

Most entrepreneurs and manufacturers discover out that the old technique of manufacturing electronic products and PCB board printed circuit board components is daunting as a result of it is gradual, error-prone and expensive. It’s not designed for small batch runs and prototyping, or to support a large number of orders and requires a long preparation time. Fortunately, Turnkey Printed Circuit Board (PCB) part providers at the moment are meeting the needs of hardware designers. In case you have almost any inquiries about exactly where as well as tips on how to employ PCB board; www.socialbookmarkssite.com,, you are able to e-mail us with our web-page. What’s a turnkey printed circuit board assembly? This is a brand new technique that impacts land-based digital elements. PCB manufacturing and cloud-based mostly software program provide entrepreneurs, manufacturers, engineers, and small companies with stress-free and quick emerging printed circuit boards. With this, you solely have to add the design of the file and receive the citation immediately, and the remainder will be taken care of by the producer. Turnkey PCB assembly goes beyond the board of directors for certain providers. Provides the required providers to launch your finished product. Customers’ products will be assembled as needed, and their parts information will be stored. The hardware designer is joyful as a result of Turnkey PCB assembly offers new alternatives. 1) Instant quote: The design of traditional PCB manufacturing strategies has not elevated the pace. Usually, as long as the cost of the order is known, the designer must wait for a very long time. But with the new Turnkey PCB assembly, this is not the case. 2) Prototyping: The production of first prototype is normally sluggish and expensive. With this, trivial issues like out-of-inventory ingredients, sluggish delivery occasions, and retaining in contact with many sellers all over the world turn into tedious. With Turnkey PCB assembly, people can now prototype more effectively and effectively. Iterating merchandise and quickly entering the market at a low value has never been easier. 3) Online ordering, monitoring and reporting: An internet portal that simplifies document management, ordering and monitoring, and facilitates fast PCB assembly. You can log in and look at the real-time standing of the job, and when the job reaches a key milestone, you will receive electronic mail notifications and alerts. 4) No need to handle multiple positions: The turnkey method to printed circuit board construction means you don’t have to fret about managing many sellers. This is particularly advantageous if the vendor must assemble your last product. Miscommunication, delay, frustration and disappointment are issues of the past. 5) Order 1 or 10,000: The turnkey PCB assembly producer has a system that may carry collectively small orders and combine them into a big run. Once the design is perfect, your turnkey PCB assembly partner can be completely satisfied to have the ability to manufacture your design in the required quantity. As what you are promoting grows, you may maintain the identical associate. 6) Delivery service, inventory and product assembly: In addition, the ultimate shipping service, stock and meeting and merchandise are produced by prime fast PCB manufacturers. You’ll be able to ship materials and parts, make complicated merchandise, and think about your stock with out calculating reels or touching boxes. Some distributors present APIs to combine with your e-commerce or ERP answer. With none stress or delay, the customer’s order is shipped directly from the manufacturers. 7) People who can use turnkey PCB assembly: Anyone with a design can quickly and economically come up with their new concepts, as a result of this new method of printed circuit board manufacturing eliminates the limitations inherent in amount and price. Legacy system. For begin-ups and small companies that need to carry products to market without substantial stock risks and pcb assembly costs, turnkey PCB assembly is just an idle technique of use. In addition, it is useful for Kickstarter manufacturers who may not know whether they only want lots of or just a few circuit boards. Manufacturers and amateurs additionally get pleasure from the flexibleness and speed of instantaneous PCB development. Engineers in large companies also assume it is quicker, printed circuit board easier, and more engaging than conventional strategies. 8) From concept to delivery: Producers management the whole course of through turnkey PCB assembly. The process consists of element procurement, PCB manufacturing, packaging, PCB assembly, implementation and testing. When you have got the best accomplice, you’ll be able to eliminate the problem of storing, shopping for, and monitoring stock, as properly because the complexity and delays constructed into traditional strategies. Now, once you focus on perfecting your design, you can also make PCB sellers worry about other issues. Modern PCB manufacturing is an efficient connection between lean manufacturing and online know-how. This makes it potential to obtain a prototype within a few days, ship the fully assembled product directly to the customer, and quote inside a couple of minutes. As more modern products and better high quality products enter the market with fewer creative limitations, everyone is profitable.

See How On The Following Image

If you are a bug lover, this tiny gadget is just for you! The Hex Bug is a tiny robot that reacts to sound and touch. These cute little pests use sensors that act like ears and whiskers. The brain of the bug — or the printed circuit board — carries instructions to very important components of the robot. The battery compartment is located beneath the stomach of the bug and is closed with a single screw. The printed circuit board carries electricity from the batteries seen right here. This tiny microphone serves because the bug’s ear. It interprets the strain from sound waves into electrical impulses. The Hex Bug’s antennae are much like the cat’s whiskers. See how on the following image. Whiskers are important to assist cats resolve whether or not they will match via narrow spaces. Springs enable the Hex Bug to do the identical thing. If the antennae touch the edges, the bug is aware of the space is just too slim. When the antennae touch an object, the spring bends and touches the electrode. Go to the following image to see why this is necessary. At the bottom of every antennae, a small spring winds round a plastic insulator (black). If you adored this article and also you would like to get more info pertaining to PCB (https://pbase.com/) please visit our site. This insulator retains the spring away from a steel electrode inside. When the spring touches the electrode this completes a circuit. This circuit tells the motor to vary course and the bug backs up. A series of gears are chargeable for the Hex Bug’s movement. The motor turns a very small gear that connects to different gears. These gears carry the motor’s motion to the bug’s center legs. The middle legs connect to the front. Back legs with small plastic bars. The center legs push and pull the bars, which causes the entrance and back legs to move. The Hex Bug’s power switch slides back and forth to the “on” and “off” positions. As the facility switch slides between the “on” and “off” positions, it’s carrying a small piece of metal. The steel is in place to touch two electrodes. This contact completes the circuit between the batteries and the remainder of the bug. When the Hex Bugs back up, PCB board article a easy clutch keeps the left legs from shifting. Both center legs attach to shafts. The right shaft matches by means of a spiral, and the left connects to the housing seen right here. When the motor turns, the spiral-pointed end suits right into a notch in the housing. The housing turns, making the left legs transfer. When the motor reverses, the point slips past the notch, so the left legs keep nonetheless. To study more, take a look at our Gadgets Channel.

Invention And History Of PCB – Printed Circuit Board

To make an digital system, the printed circuit board performs a central function. It follows the design process that converts an electronic schematic (designed by the circuit designer) right into a physical circuit board. However, there are three other ways to design the PCB, a single-sided PCB, a double-sided PCB, and a multi-layer PCB. These three varieties used two sorts of applied sciences, the through-hole know-how, and the floor mount expertise. But, these technologies received formulated by the long strategy of innovations in history. So, in this text, we’ll talk about the invention and historical past of the PCB. Before the invention of the PCB construction, the point-to-point formation was widespread for the printed circuit board. However, it was not important and very questionable. Therefore, In the 1920s designers makes use of baseline or outdated thin pieces of wooden. And, the holes were drilled into that wooden material. And flat brass wires utilized onto it. The first software of those boards had been gramophones and radios. Then the invention of Printed Circuit Boards happened. The first PCB was developed in 1936 by Austrian designer Paul Eisler. At that time, it was designed to function radio programs. Meanwhile, the United States army adopted this methodology. And, make the most of this in proximity fuses in world warfare two. In 1948 this printed wiring board started to evolve. JLCPCB is the foremost PCB prototype & manufacturing company in china, offering us with the perfect service we now have ever experienced regarding (Quality, Price Service & Time). We strongly advocate ordering PCBs from JLCPCB, all you could do is just download the Gerber file and upload it to the JLCPCB website after creating an account as mention in the video above, visit their web site to search for extra! The designer, Eisler within the 1940s invented the more inventive design of PCB. It consists of the etching of circuits onto the copper foil. In the 1950s when the transistor obtained introduced available in the market, the design received extra modification. For the reason that translator have small in size so PCB acquired improved. After that, PCBs get superior right into a double layer. That comprises electronic elements on one layer. Printing on the other side. Therefore, to prevent boards from degradation, zinc plates, and resistant material got launched. Then, Within the 1960s printed circuit boards are wrongly related to the harmful chemical polychlorinated biphenyl. If you loved this short article and you would like to receive far more information relating to pcba why kindly go to the web-site. To clarify, PCB is renamed as PWB, Printed Circuit Board Review that’s Printed Wiring board. Afterward, a brand new standard method for designing was discovered. Now, photo imageable polymer coating is applied on to circuits. Within the 1980s, surface mount know-how was found. Before that technology parts had been soldered into the holes. However, in SMT parts were soldered directly into small pads. Without the necessity for holes. It will get extra standard as this know-how was more reliable and has a low price. Within the 1990s the scale of the Printed circuit board will get reduced. In consequence, it improves reliability. In the 2000s it turns into smaller. Flexible and multilayer become more distinguished. Most electronic gadgets used this for prime pace. The PCB of the modern era is essentially employed within the electronic industry. Single-layer, double layer, multi-layer, rigid, versatile. Every form of different PCBs is used for different functions. PCBs are now evolving. Growing day-to-day. We have discussed the invention and historical past of PCB. In conclusion, we can say that the invention of the PCB made the designer’s lives simpler. Since Printed circuit boards have developed rather a lot. But, nonetheless rising. Because technology can’t cease the technique of evolvement. There’s all the time some area for progress.

Invention And History Of PCB – Printed Circuit Board

To make an digital system, the printed circuit board plays a central function. It follows the design course of that converts an digital schematic (designed by the circuit designer) into a bodily circuit board. However, there are three alternative ways to design the PCB, a single-sided PCB, a double-sided PCB, and a multi-layer PCB. These three types used two kinds of applied sciences, the by-gap know-how, and the floor mount technology. But, these technologies obtained formulated by the lengthy technique of inventions in historical past. So, in this article, we’ll discuss the invention and historical past of the PCB. Before the invention of the PCB development, the purpose-to-point formation was widespread for the printed circuit board. However, it was not vital and really questionable. Therefore, In the 1920s designers makes use of baseline or outdated thin items of wood. And, the holes were drilled into that wood materials. And PCB price flat brass wires utilized onto it. The first utility of those boards were gramophones and radios. Then the invention of Printed Circuit Boards happened. The primary PCB was developed in 1936 by Austrian designer Paul Eisler. At the moment, it was designed to operate radio programs. Meanwhile, the United States navy adopted this methodology. And, utilize this in proximity fuses in world warfare two. In 1948 this printed wiring board started to evolve. JLCPCB is the foremost PCB prototype & manufacturing firm in china, offering us with the most effective service we’ve ever skilled regarding (Quality, PCBA Price Service & Time). We strongly advocate ordering PCBs from JLCPCB, all that you must do is simply obtain the Gerber file and upload it to the JLCPCB website after creating an account as mention in the video above, visit their website to search for extra! The designer, Eisler within the 1940s invented the extra artistic design of pcb assembly. It includes the etching of circuits onto the copper foil. In the 1950s when the transistor got launched in the market, the design obtained more modification. For the reason that translator have small in measurement so PCB bought improved. After that, PCBs get advanced into a double layer. That accommodates digital components on one layer. Printing on the other aspect. Therefore, to forestall boards from degradation, zinc plates, and resistant materials acquired launched. Then, Within the 1960s printed circuit boards are wrongly related to the dangerous chemical polychlorinated biphenyl. To clarify, PCB is renamed as PWB, that is Printed Wiring board. Afterward, a brand new customary method for designing was discovered. Now, picture imageable polymer coating is applied on to circuits. In the 1980s, floor mount expertise was discovered. Before that know-how elements had been soldered into the holes. On the other hand, in SMT elements were soldered immediately into small pads. Without the need for holes. It gets extra popular as this technology was more dependable and has a low price. In the nineteen nineties the size of the Printed circuit board gets reduced. Consequently, it improves reliability. Within the 2000s it becomes smaller. Flexible and multilayer change into extra prominent. Most digital units used this for prime velocity. The PCB of the modern era is basically employed in the electronic industry. Single-layer, double layer, multi-layer, inflexible, flexible. Every sort of different PCBs is used for various purposes. PCBs are now evolving. Growing daily. If you have any issues about wherever and how to use PCB price, you can speak to us at the internet site. We have mentioned the invention and historical past of PCB. In conclusion, we will say that the invention of the PCB made the designer’s lives simpler. Since Printed circuit boards have evolved too much. But, nonetheless rising. Because technology can’t cease the means of evolvement. There’s at all times some area for development.

England Will Now Play SEVEN T20 Matches When They Tour Pakistan

England will now play seven T20 internationals after they visit Pakistan in September and October next yr. And the Pakistan Cricket Board has introduced that two additional T20 fixtures have now been added to the 5 already scheduled. They may offer preparation for the T20 World Cup set to be staged in Australia in October and November 2022, earlier than England then return to Pakistan for a Test series. If you have any concerns concerning the place and how to use pcba (try what he says), you can get hold of us at our own website. It came after the ECB chief executive Tom Harrison flew to Pakistan to fulfill the country’s prime minister Imran Khan. PCB chief govt Ramiz Raja in an effort to restore strained relations. PCB officials had been left furious when England PCBA pulled out of their latest tour – which additionally included numerous white ball video games for the girls’s team – at short notice. The ECB cited safety issues within the wake of latest Zealand abandoning their very own tour on the morning of the opening ODI in Rawalpindi. It was particularly galling for Pakistan after they got here to England amid the Covid-19 pandemic to avoid wasting the 2020 Test match summer time. Staying in a strict bio-safe bubble, Pakistan played three Tests and three T20s behind closed doors at Old Trafford and the Ageas Bowl. England have not toured Pakistan since late 2005 but that may change subsequent yr. Harrison said: ‘Myself and ECB’s Senior Director Martin Darlow visited Lahore to talk face to face with the PCB round some of the things which have occurred over the previous few weeks, resulting in the cancelation of our tour in October. We also wished to discuss the long run as the 2 boards have a historic relationship. Want to maneuver the agenda in the direction of a ahead-wanting one as opposed to one looking back. We’ll then return after the ICC Men’s T20 World Cup in Australia to complete the Test match aspect of that tour. That is simply to reaffirm our commitment to Pakistan cricket to getting England teams, males’s and ladies’s teams, ultimately taking part in in Pakistan at dwelling. I do not think there’s a cricketer in England who does not need to test their talents in opposition to the huge talent this country has and within the circumstances they know greatest. We additionally talked with our colleagues at the PCB around pathway engagement, how we will help proposals across the women’s game and a few attention-grabbing ideas across the home agenda here in Pakistan. Raja said: ‘The ECB have shown their massive heartedness to be here for which I am thankful to Tom and PCBA Martin. It means too much to us. We put in lot of efforts to make sure that each one visiting teams are comfortable in Pakistan.