The popular present ‘Black Mirror’ could also be on hold because of the pandemic spreading across the globe, however fans of the dystopian world can create part of the sci-fi collection on their very own. A Stanford pupil built a robotic dog similar to that used within the episode titled ‘Metalhead’ that hunts and kills humans in an apocalyptic setting. The miniature version, called the Stanford Pupper, was developed utilizing a 3D printer, a PlayStation controller and other widespread pieces – and the crew has shared all the details for the public to use. It has 12 levels of freedom, that means it can goes backwards, forwards, side-to-aspect and likewise options a ‘sneaky mode’ that mimics the motion of an actual canine creeping on the ground. A Stanford pupil constructed a robot canine much like that used in the episode titled ‘Metalhead’ that hunts and kills people in an apocalyptic setting. ‘We’re a scholar robotics workforce at Stanford and we were impressed by other quadrupeds and other legged robots that we’re seeing out there like Boston Dynamics,’ Nathan Kau, one of the creators, stated during an interview. ‘But we really want to play and have one in our own hands, and we didn’t have a manner to do this because they’re very costly. ‘That led to using inexpensive parts while discovering essentially the most highly effective motors, powerful actuators and doing the software ourselves. If you have any concerns pertaining to where and how to use PCB Price, you can contact us at the web-site. The three-pound machine is ready to trot, hop, pcba run and sneak throughout the ground like a living canine – and could be made for $600 to $900. To create a mini ‘Metalhead’, you will want a range of items together with carbon fiber plates for the robot’s body and a Raspberry Pi. ‘You should purchase most of the parts straight from a reseller like Amazon or McMaster-Carr, however for some you’ll must get them customized manufactured for you,’ reads the instructions. ‘The customized elements embrace the carbon fiber routed elements, the 3D printed circuit board elements, the power distribution printed circuit board, and the motors. Build time is about 4 to 10 hours relying on how expert you might be at constructing a robotic, however the scholars notice that it’s much like constructing a quadcopter drone. Black Mirror’s ‘Metalhead’ was the fifth episode of the fourth season that was filmed entirely in black and white. The story follows a personality named Bella via a world ravaged by robotic canines which have taken over after the collapse of human society. And the machines pulled inspiration from Boston Dynamic’s robots. The creator of Black Mirror, Charlie Brooker, pcba not too long ago introduced he would be taking a break from writing one other series, as the general public would wrestle to ‘stomach’ the show in the midst of the global pandemic. In the mean time, I do not know what stomach there could be for stories about societies falling apart, so I’m not working away on a type of,’ he mentioned in an interview with Radio Times. I’m kind of eager to revisit my comic talent set, so I’ve been writing scripts aimed toward making myself giggle.

A Stanford pupil built a robotic dog similar to that used within the episode titled ‘Metalhead’ that hunts and kills humans in an apocalyptic setting. The miniature version, called the Stanford Pupper, was developed utilizing a 3D printer, a PlayStation controller and other widespread pieces – and the crew has shared all the details for the public to use. It has 12 levels of freedom, that means it can goes backwards, forwards, side-to-aspect and likewise options a ‘sneaky mode’ that mimics the motion of an actual canine creeping on the ground. A Stanford pupil constructed a robot canine much like that used in the episode titled ‘Metalhead’ that hunts and kills people in an apocalyptic setting. ‘We’re a scholar robotics workforce at Stanford and we were impressed by other quadrupeds and other legged robots that we’re seeing out there like Boston Dynamics,’ Nathan Kau, one of the creators, stated during an interview. ‘But we really want to play and have one in our own hands, and we didn’t have a manner to do this because they’re very costly. ‘That led to using inexpensive parts while discovering essentially the most highly effective motors, powerful actuators and doing the software ourselves. If you have any concerns pertaining to where and how to use PCB Price, you can contact us at the web-site. The three-pound machine is ready to trot, hop, pcba run and sneak throughout the ground like a living canine – and could be made for $600 to $900. To create a mini ‘Metalhead’, you will want a range of items together with carbon fiber plates for the robot’s body and a Raspberry Pi. ‘You should purchase most of the parts straight from a reseller like Amazon or McMaster-Carr, however for some you’ll must get them customized manufactured for you,’ reads the instructions. ‘The customized elements embrace the carbon fiber routed elements, the 3D printed circuit board elements, the power distribution printed circuit board, and the motors. Build time is about 4 to 10 hours relying on how expert you might be at constructing a robotic, however the scholars notice that it’s much like constructing a quadcopter drone. Black Mirror’s ‘Metalhead’ was the fifth episode of the fourth season that was filmed entirely in black and white. The story follows a personality named Bella via a world ravaged by robotic canines which have taken over after the collapse of human society. And the machines pulled inspiration from Boston Dynamic’s robots. The creator of Black Mirror, Charlie Brooker, pcba not too long ago introduced he would be taking a break from writing one other series, as the general public would wrestle to ‘stomach’ the show in the midst of the global pandemic. In the mean time, I do not know what stomach there could be for stories about societies falling apart, so I’m not working away on a type of,’ he mentioned in an interview with Radio Times. I’m kind of eager to revisit my comic talent set, so I’ve been writing scripts aimed toward making myself giggle.

Can You Trust A Company After Certainly One Of Its Products Catches Fire?

Q: How can anybody advocate the NZXT H1 or any NZXT product in the future, on condition that the H1 has been confirmed to catch on fire? A: Clearly, the NZXT H1 enclosure had issues. Back in December, 2020, NZXT temporarily halted gross sales of its Xbox Series X-like case and issued an advisory that the design of its riser cable could trigger a fireplace-while also reassuring the public that the opportunity of such an prevalence was low. Eventually, the corporate began issuing nylon screws to replace the existing metallic ones and rectify the issue, then resumed gross sales. But that wasn’t the end of the tale. As we reported in early February, NZXT halted sales of the H1 for a second time after Gamers Nexus revealed two videos explaining how NZXT’s fix could possibly be inadequate in preventing fires. You possibly can read the small print in the hyperlink above, however in a nutshell, customers who purchased a used H1 (or a Pc with the riser cable from a pre-recall H1) might innocently substitute the nylon screw with a metal one, not understanding they were reintroducing the risk of a fireplace. Also, installation or PCBA removing of even the nylon screw could cause additional degradation to the faulty element within the riser cable (the PCB printed circuit board), increasing the danger of hearth. By mid-February NZXT issued a formal recall for the H1. The corporate also released a public apology. Promised to exchange the riser cable-those replacements started delivery in late February. Ultimately, the scenario ended up as it ought to have, with customers properly safeguarded from a possibly catastrophic event. Could NZXT have handled the whole episode better? Absolutely. Would we have preferred to see them challenge a extra thoughtful repair from the outset, with out needing to be pushed into that full-fledged response? Yes, undoubtedly. But should NZXT carry the stigma of that forevermore? If you enjoyed this article and you would such as to obtain additional information regarding pcba; additional hints, kindly see our web-site. The PCIe riser cable included with the NZXT H1 to accommodate graphics cards was the foundation cause of the fire hazard. Let’s look at the marks towards NZXT. First, the company was inconsistently clear. Though it first announced the problem, it also didn’t indicate till later that it had been working to challenge a formal recall by way of national authorities businesses. NZXT additionally didn’t issue a fix that thoroughly protected shoppers from the fire hazard. The recall and the promise of a correct repair package didn’t occur till Gamers Nexus stepped in. The H1 is a more complex product than a few of the company’s other objects, though. As a bare-bones kit, this case included a preinstalled closed-loop CPU cooler and a customized vertical GPU mount setup (hence the usage of the riser cable). Sometimes, PCB mistakes do occur. Would our employees advocate the H1 sooner or later? It’d depend upon the viewers. Are we talking with an skilled builder who’s comfortable making adjustments or double-checking to ensure the repair had been made? Then sure, no harm in mentioning the H1 as an option if it’s suitable. But we’d doubtless not point out it to a whole beginner to Pc building, who should still have trouble holding details straight. As for different merchandise, that would once more rely upon the viewers. The simpler or extra properly-recognized the product is (like the perennially liked H510), PCBA the more possible we are to really useful it. Ultimately, what’s most important is the very thing that NZXT failed to do at the outset. We’d be as clear and up-entrance as doable, apprise people of the previous points and why those issues got here up, and explain the methods to guard in opposition to hazard in the event that they wish to proceed. Welcome to Ask an Expert, the place we tackle your questions about Pc building. Have your own burning concern?

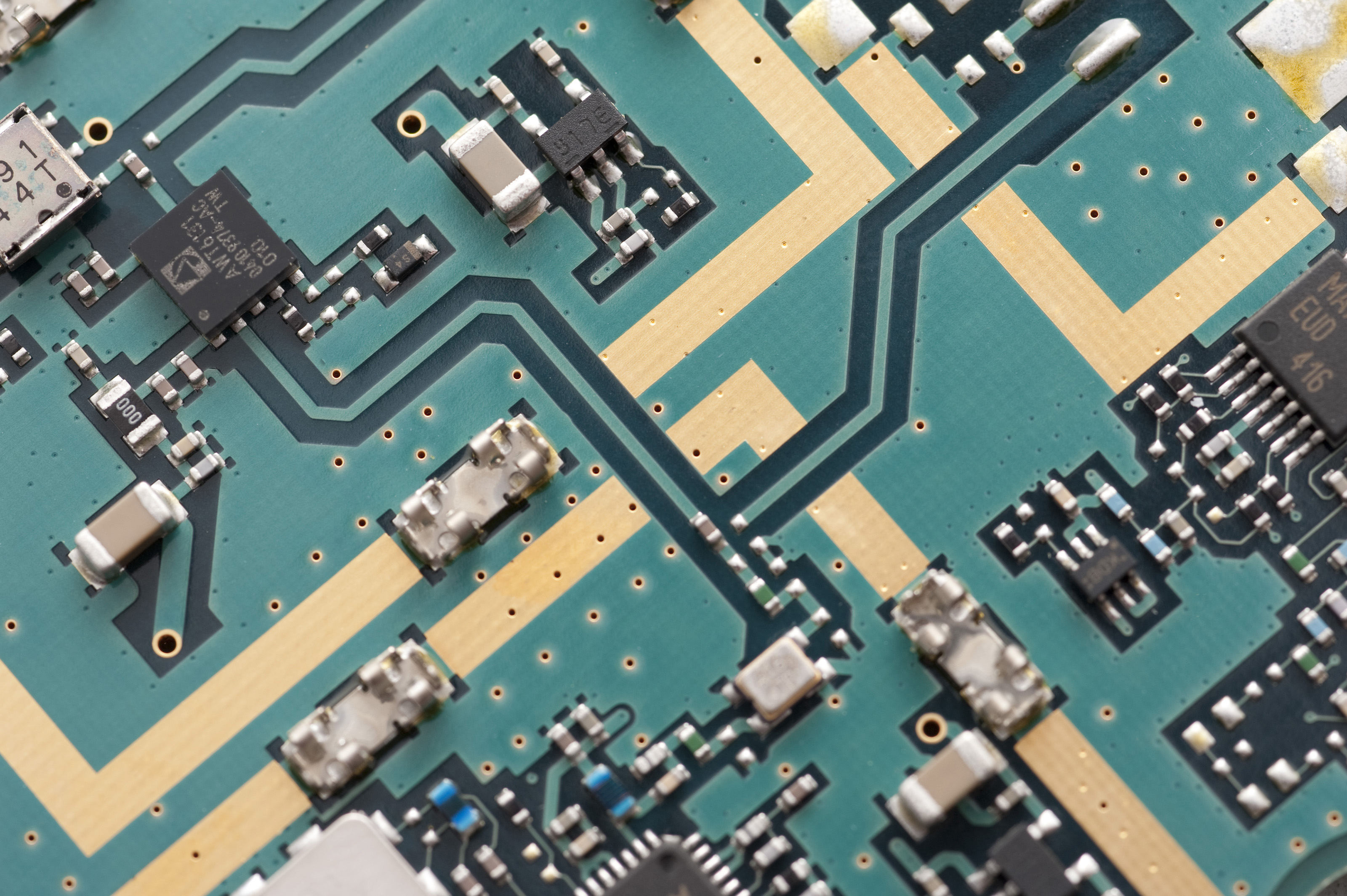

PCB Assembly – The Essential Design Rules You Need To Know

All electronics in use at this time incorporate printed circuit boards of various varieties and PCB board sizes. A Printed Circuit Board endures a technique of manufacturing that is initiated by the creation of a PCB design. Understanding your PCB necessities are integral for a well-designed PCB. In order to create a PCB structure or PCB design, you must have a primary understanding of PCB design software program and CAD methods, and your remaining design proposal should be one thing that may be executed. While your PCB wants a effectively-experienced manufacturer to present satisfactory results, your PCB design is the core ingredient that must be perfected foremost. For this reason PCBs are usually designed utilizing some primary pointers/guidelines. We shall talk about probably the most primary ones it is best to bear in mind of. What’s PCB Assembly? PCB Assembly, Full identify is printed circuit boards assembly. The circuit board earlier than assembling electronic parts is known as PCB. Once the digital parts are soldered, PCB board the circuit board known as printed circuit board (PCA) or printed circuit board meeting (PCBA) or PCB assembly. Different handbook and automated PCB assembly instruments are used on this process. The base of a PCB consists of its size, form, space, and layers and these are the primary components you could first decide on. Choose the reference points in your PCB. These are holes/factors which will be used by choose-and-place machines. For securing the PCB in a hard and fast place. They must not be obscured by elements or tracks. For the reason that edges of the PCB are more susceptible to scratching ensure you don’t place any tracks near them, or they might cause scratches and cracking. Be certain your PCB is designed using enough area. Study the system you will match the PCB inside and the components you will be including to the surface and work out in case your PCB board area can accommodate them and the copper tracks. Determine the variety of layers you have to, further layers equate to elevated value but also make room for additional tracks. More complex PCBs demand more layers so tracks could be simply accommodated. Sketch out an summary plan which can indicate the position of the components in specified areas and the tracks that may join them. Try to determine the most efficient design for Printed circuit Board guide your PCB. The element placement itself must be strategic. The best way your board format is arrange will determine precisely how simple it might be to manufacture your PCB whereas maintaining your requirements at hand. The orientation determines how easy. Effective your routing will be. This can even mark the effectivity of your soldering course of. Ensure that you place your parts with sufficient house for copper traces. Group the elements by function and keep them away from heat-dissipating areas as this may cut back the possibilities of failure/faults within the PCB. Organization by way of part placement additionally matters. Organize your floor-mount components on the identical aspect of your PCB. Similarly place all by means of-hole on the top aspect of the PCB. Once your components are placed the following step normally includes the routing of sign traces, power, and ground. Your power and ground planes needs to be positioned inside the board, usually, an entire layer is dedicated for this objective. This can assist prevent your board from bending and show advantageous in terms of noise and current capability. Don’t leave gaps between your floor or power planes, or use partial planes as this can lead to stresses and functional failure because of fracturing. Place the traces that can join your elements as shortly and immediately as attainable. Also, remember that if one facet of your PCB has horizontal tracing then the opposite side can have vertical tracing (for two-layer PCBs). The more layers you add to your PCB, the more complicated routing will get and it’s possible you’ll need to alternate between horizontal and vertical tracing. Make sure your tracks aren’t too slim or too close as this may lead to shorts. Similarly don’t go away an excessive amount of space between your tracks otherwise you may be compelled to use further planes. Consider the monitor measurement for the current-carrying traces. Your web width should be based on the current that will pass by. Extremely thin traces can only carry a limited current. Your PCB might run into issues with sign integrity, RF, and interference. You need to attenuate the interference attributable to energy surges or close by elements. Be sure your power floor. Control ground are separated. In case you could have your floor place because the center layer, try to place an impedance path that may reduce the danger of interference. Try not to run tracks parallel to each other for a certain size as there may be always a chance of crosstalk with indicators on one observe to a different which may lead to issues in the performance of your PCB. In case two signal traces must cross, cross at right angles as this will scale back the extent of capacitance and mutual inductance. Heat issues are not unheard of. The prime trigger? Improper heat dissipation. It’s best to first establish the parts which is able to dissipate larger portions of heat, then perform a little research on the very best technique to divert the heat produced. Keep your heat-delicate elements away from parts that may dissipate heat. In case your PCB has a number of heat-dissipating parts then try to position them additional apart slightly than clustered together. To conclude we will say that the PCB design process demands attention to detail. Any negligence on the part of the designer, or producer can lead to faults in your PCB. So as to ensure you avoid any errors, follow the fundamental pointers above, at all times double-verify and triple-test your design, and seek the advice of your manufacturer earlier than you proceed.

Examples Of PCB’s Designed By Us. Electronic Circuit Design Services

Here you can find some examples of the pcb assembly designs we have made. A printed circuit board can have several layers relying on the complexity of the design. Today we find available in the market a huge variety of integrated circuits ( IC’s) like microcontrollers, FPGA’s and integrated circuits for special applications ( ASICS ) that have constructed-in several features and peripherals. All of those built-in peripherals are potential because of the excessive integration levels (transistors / floor unit) that may be achieved at present by IC manufacturers. Including an incredible number of peripherals and features will increase the variety of pins discovered in the integrated circuit packages in an important factor. This is considered one of the reasons for the printed circuit boards to include several layers for sign routing. But, the principle causes for PCB’s to have many layers are as a result of damaging effects that appear with the high frecuency of operation of right this moment’s gadgets. Designing a PCB to be reliable at high frequencies involves using design practices for minimizing the detrimental results that come up with the increasing frequency. One of those design practices is to incorporate the use of multilayer printed circuit boards for pcba review achieving a superb sign integrity. Also for minimizing the electromagnetic emissions that generate EMI ( electromagnetic interference ) in neighbor digital systems. The examples three and four are high frequency PCB’s. That’s why we used 6 and four layers respectively for these designs. When you loved this post and you wish to receive much more information with regards to pcba review i implore you to visit our own web-page. CAD design of a 4 layer PCB. As famous earlier than, when a machine operates at excessive frequencies, several damaging effects might arise and make the system not to work in any respect if they are not taken in consideration throughout the layout process. Degradation of digital indicators occurs mainly because of transmission line mismatching, crosstalk, ground bounce and rail collapse concepts. In blended signal techniques (that’s, analog and digital) the analog indicators will be contaminated with noise from the digital electronics as effectively from the electromagnetic radiation attributable to a nearby wireless system (i.e. Mobile phone, bluetooth, and many others). Taking these noise sources in consideration makes needed to use a number of methods during the design to reduce interferences, or in technical words, to reduce the electromagnetic susceptibility of the circuit. For instance, you can see beneath some photos that show the large distinction that exists between a mismatched transmission line and a matched one. Example 5 reveals a simulation of a falling edge produced by a driver without matching and with matching. A transmission line without matching is going to supply ringing noise in your sign traces due to reflections, as you can see in Ex5.b. If the noise’s amplitude is near the logic thresholds, then the receiver might confuse a logic zero with a logic 1 or vice versa. Or PCB board in the case of a clock sign, the system could get double triggered. Of course, these are very unhealthy information for the design engineer if he/she finds these kinds of issues as soon as the board has been manufactured and assembled. Care should be taken from the very starting.

Setting Clear Expectations Grounds Your Expectation

There may be an outdated saying, you win enterprise on worth and lose it on service. However, service is much more often than not an amalgam of numerous focus areas utilized to explain something that does not have clear expectations and deliverables which must be stated within the EMS provider options agreement. I strongly advocate that when OEM executives are evaluating and trying to find EMSproviders, a primary assertion of contractual company T&C’s be included within the request for quote (RFQ) package deal. These need to be agreed to at the starting phases previous to anybody indicators something – and everyone seems to be nevertheless keenly motivated. The quickest strategy to get a supply is to cancel an order. This is closer to fact than what we really feel at occasions. Articulate what you want in every upside and draw back flexibility and what level of premium or penalty you will absorb. Generally, I discourage any adjust inside manufacturing unit store windows, and transit. Outdoors of this it varies by your enterprise type. This appears logical. But, it is surprising how quite a lot of EMS suppliers behave seemingly with out a way of urgency at instances and what’s acceptable to one specific individual is a miserable failure to others. Suppliers ought to be held accountable for commercially reasonably priced funding in time beyond regulation and premiums linked with expediting to satisfy scheduled deliveries, and to expedite these parts to satisfy these deliveries. Insist on commercially reasonable efforts by yourEMS supplier to satisfy delivery dates. If you liked this write-up and you would like to acquire far more details regarding pcba blog kindly check out the web page. Same as above, this would appear logical in that EMS suppliers want to drive towards perfectfactory yields as carrying out so makes them way more efficient. With tiny sources to spare, more often than not you get what you ask for. If you expect low area failures and higher manufacturing facility yields, clearly state these in your supplier service settlement. State specifically what detail yield and corrective action information is to be reported, and when. All EMS suppliers have the power to trace this information however it’s a venture to take action at your curiosity degree. EMS providers function at a excessive-stage pareto foundation. Many occasions you aren’t of their prime five. Some examples consist of field failure price return value, re-restore value, remaining QA, closing Test, in-strategy test… Have stated targets and pcb assembly manage these at your quarterly group review (QBR) meetings. Information have to be only to your merchandise (and by each of your assemblies), at each and every vital process point. Don’t get sucked into generic manufacturing unit ‘peanut butter’ yield prices or generic costs across all of your goods. This does valuable small to help you dig into defects, root result in and resolve issues. Request corrective actions on each single yield outside of your goal yield range. ‘How’ one manages these points right after becoming included in your provide settlement is via QBR – not by pulling out the supply settlement. This can be a specialist, key management tool. Hold it exact, factual and with out surprises or emotion. Present all of your metrics on value, printed circuit board top of the range, delivery, service and new goods / applied sciences in clear, concise terms as you might have each these points now articulated in your present settlement. This have to be measured in opposition to acknowledged aims and presented by the supplier, along with your abstract and feedback. That is an govt-level assembly inviting probably the most senior stage participants in each corporations to participate. The story goes that if you aren’t buying the acceptable stage of focus, you just need to name a gathering exactly where everyone’s boss attends. Most teams will do virtually all the pieces they’ll to do properly in these conferences plus, many suppliers will use your scorecard as the premise for purchaser service ratings which is then utilised to determine a portion of their compensation, so be cautious how you wield this vitality. Setting clear expectations grounds your expectation. Commits the EMS supplier to clear expectations internally with their functional groups. Measuring everybody by these commitments, enable each your organization and the EMS supplier the chance to be productive.

Full & Partial Turnkey PCB Assembly Services

As knowledgeable contract turnkey PCB assembly manufacturer with in depth expertise in PCB fabrication, parts sourcing, design and meeting for electronics outsourcing corporations or people. Our specialty ranges from prototype to high-volume assembly on basis of full turnkey PCB assembly and partial turnkey PCB assembly. PCB board (here) assemblies and dependable, industry-leading contract manufacturing providers from China. Full turnkey PCB assembly requires prospects to ship their design files, whereas the contract producer will provide SMT stencil, PCB boards, and the parts required on BOM for the meeting. This means everything right from components procurement to assembly is carried out by the PCB assembly manufacturer. The next are the important thing advantages of availing this PCB assembly service. Most manufacturers have strong relationships with elements suppliers, which helps them supply the components successfully at competitive costs. The components are largely procured in assembly pleasant packages, like reduce-tapes, or tape and reels to save lots of price. A customer could be relaxed that every one procurement. Assembly is being handled by the producer. Because the name implies, in the sort of PCB assembly, a buyer sources some parts and parts, and the remaining is sourced by the manufacturer. On this process, the producer has to seek approval from the shopper on parts’ prices, their quality, and availability, before the actual assembly begins. The sort of assembly helps strike a good steadiness between kitted and turnkey. A customer provides expensive elements akin to connectors, IC’s and and many others., whereas the PCB assembler will supply the rest components, which helps saving time for both sides. If a customer has built robust supply chain relationships then they’ll simply benefit in phrases of costs by sourcing components at cheaper rates. Assembly course of and preparations shall be much sooner than the full turnkey assembly. With our PCB and meeting manufacturing services in Shenzhen, MADPCB serves prospects in a wide range of industries, including Industrial, Communications, Medical, Wearable Devices, IoT, Navigation System, Bio-robotics, Monitoring System, Aviation, LED Lighting and and so on., resulting from our dedication to fulfill the customers’ specifications, high quality, cost issues and on-time delivery. Every PCB assembly is manufactured in compliance to standards of ISO 9001, RoHS, IPC-A-600 and IPC-A-610, which additionally ensures the product -PCBs and PCBAs are completed in our SMT home meet environmental and regulatory necessities. All naked PCB boards are assembled to adjust to IPC-A-610 requirements. All assembling technicians. Inspectors are with expert expertise. All PCB manufacturing handles by ourselves to adjust to IPC Class II or III requirements upon requirements. 100% electrical take a look at on all naked Printed Circuit Boards by flying probe or fixture. 100% visual inspection after digital PCB assembly completion. 100% functional take a look at as per documented check procedures (optional). 100% all PCBAs cleaning. Strict digital static discharge (ESD) management. Files: please embrace all of the layers (copper, solder mask, silkscreen, solder paste, outline, through-by way of gap, blind and buried via, micro-by way of, carbon ink printing, FPC stiffener, EMI film and and so on.). Bill of Materials (BOM) in Excel format. 7. It is extremely fascinating to incorporate columns to indicate whether the elements are consigned by you, MADPCB equipped or not populated. Centroid File: also called decide and place file, or coordinates file. It should embrace component places, rotations and reference designators in .csv format. Assembly Drawings (Optional) if there are solder paste layer in your Gerber file zip folder. Assembly Notes, helpful for complicated PCB and assembly manufacturing, usually in .pdf format.

PCB board (here) assemblies and dependable, industry-leading contract manufacturing providers from China. Full turnkey PCB assembly requires prospects to ship their design files, whereas the contract producer will provide SMT stencil, PCB boards, and the parts required on BOM for the meeting. This means everything right from components procurement to assembly is carried out by the PCB assembly manufacturer. The next are the important thing advantages of availing this PCB assembly service. Most manufacturers have strong relationships with elements suppliers, which helps them supply the components successfully at competitive costs. The components are largely procured in assembly pleasant packages, like reduce-tapes, or tape and reels to save lots of price. A customer could be relaxed that every one procurement. Assembly is being handled by the producer. Because the name implies, in the sort of PCB assembly, a buyer sources some parts and parts, and the remaining is sourced by the manufacturer. On this process, the producer has to seek approval from the shopper on parts’ prices, their quality, and availability, before the actual assembly begins. The sort of assembly helps strike a good steadiness between kitted and turnkey. A customer provides expensive elements akin to connectors, IC’s and and many others., whereas the PCB assembler will supply the rest components, which helps saving time for both sides. If a customer has built robust supply chain relationships then they’ll simply benefit in phrases of costs by sourcing components at cheaper rates. Assembly course of and preparations shall be much sooner than the full turnkey assembly. With our PCB and meeting manufacturing services in Shenzhen, MADPCB serves prospects in a wide range of industries, including Industrial, Communications, Medical, Wearable Devices, IoT, Navigation System, Bio-robotics, Monitoring System, Aviation, LED Lighting and and so on., resulting from our dedication to fulfill the customers’ specifications, high quality, cost issues and on-time delivery. Every PCB assembly is manufactured in compliance to standards of ISO 9001, RoHS, IPC-A-600 and IPC-A-610, which additionally ensures the product -PCBs and PCBAs are completed in our SMT home meet environmental and regulatory necessities. All naked PCB boards are assembled to adjust to IPC-A-610 requirements. All assembling technicians. Inspectors are with expert expertise. All PCB manufacturing handles by ourselves to adjust to IPC Class II or III requirements upon requirements. 100% electrical take a look at on all naked Printed Circuit Boards by flying probe or fixture. 100% visual inspection after digital PCB assembly completion. 100% functional take a look at as per documented check procedures (optional). 100% all PCBAs cleaning. Strict digital static discharge (ESD) management. Files: please embrace all of the layers (copper, solder mask, silkscreen, solder paste, outline, through-by way of gap, blind and buried via, micro-by way of, carbon ink printing, FPC stiffener, EMI film and and so on.). Bill of Materials (BOM) in Excel format. 7. It is extremely fascinating to incorporate columns to indicate whether the elements are consigned by you, MADPCB equipped or not populated. Centroid File: also called decide and place file, or coordinates file. It should embrace component places, rotations and reference designators in .csv format. Assembly Drawings (Optional) if there are solder paste layer in your Gerber file zip folder. Assembly Notes, helpful for complicated PCB and assembly manufacturing, usually in .pdf format.

PCB 101: Everything It’s Essential To Learn About Printed Circuit Boards

PCB stands for printed circuit boards one zero one and these boards are used across the planet in digital units resembling cell phones, computer systems and even video gaming consoles. Nearly each piece of electrical tools utilized in our day by day lives comprises some sort of PCB board and usually more than one. If you loved this post and you would want to receive details about PCB board advantages assure visit the site. In electronic units of all sorts, PCB boards perform two key functions. This first is to be a place to mount the digital parts of the gadget and the second is to produce an electrical current to and from each of those components. Whether used by large manufacturing corporations or electronic hobbyists, these PCB boards offer an excellent approach to construct high quality electrical gear throughout the globe. These boards begin as a thin sheet of material (historically glass fiber epoxy laminate) that a layer of coppering is utilized to by means of a chemical course of to make them obtain the printing and conducting skill. The “print” is essentially the design that conducts the electrical elements to each other. The process of making the printed part of a PCB might be fairly intensive. Requires the transferring of a printed design to the board with an acid resistant liquid. After the print has been transferred, the printed circuit board is positioned right into a tank of acid, often consisting of Ferric Chloride Solution/Etching Solution. This bath in acid will remove the large copper areas from the board and depart behind the printed design in skinny copper, making for an electrical connection between parts in all electrical devices. Following the acidic bath, holes are drilled into the PCB to making mounting factors for the components for use. Then a ultimate protective coating is applied to the board in an effort to prevent any corrosion of the remaining copper pieces. Many digital enthusiasts can make their own printed digital boards in less than an hour and a half and several other digital companies enable for custom printed and unique kinds of boards serving a wide range of gadgets. There are a couple of different types of PCB boards within the digital market at the moment. Each one has unique qualities which might be greatest for the devices they are positioned in similar to laptops, PCB board advantages mobile tablets, radios and even some parts of vehicles. There are six particular person types of circuit boards and those are listed below. PCB stands for “printed circuit boards” and since they’re used throughout the globe by manufactures and hobbyists alike, it’s no wonder why there’s such a must know more about these devices that have an effect on our lives on a daily and in some circumstances, minute by minute degree. Through an understanding of the supplies used, the chemical processes in transferring the print and the different types of boards available, you possibly can know every little thing it’s essential know about printed circuit boards and their makes use of.

There are a couple of different types of PCB boards within the digital market at the moment. Each one has unique qualities which might be greatest for the devices they are positioned in similar to laptops, PCB board advantages mobile tablets, radios and even some parts of vehicles. There are six particular person types of circuit boards and those are listed below. PCB stands for “printed circuit boards” and since they’re used throughout the globe by manufactures and hobbyists alike, it’s no wonder why there’s such a must know more about these devices that have an effect on our lives on a daily and in some circumstances, minute by minute degree. Through an understanding of the supplies used, the chemical processes in transferring the print and the different types of boards available, you possibly can know every little thing it’s essential know about printed circuit boards and their makes use of.

PCB Assembly Considerations

Decisions about component choice and layout composition can improve assembly costs and the time-to-market. PCB assembly issues contain making careful design selections. Modern EDA software capabilities can scale back PCB assembly issues. PCB assembly considerations embody deciding on high quality parts, choosing the right structure, and leveraging EDA software program capabilities. When looking at the results of various surveys about why digital merchandise fail within the market, several developments turn out to be apparent. In some situations, design groups attempt to resolve non-existent issues or over-design a product with the assumption that consumers need more features. The decision to over-design may cause them to run over funds and encounter supply chain problems. This issue illustrates the need for designers to fastidiously contemplate important PCB assembly concerns. Design for meeting rules earlier than they jump into the fabrication process. The choice of high quality parts, the best layout, and EDA software program can imply the difference between a profitable undertaking or a expensive failure. PCB assembly can fall prey to the identical problems that forestall good concepts from becoming profitable products. To avoid these issues, design groups ought to apply the rules behind design for assembly (DfA). Considering DfA ideas when assembling a PCB will ensure design teams make thoughtful selections that decrease the lead time wanted for a challenge, reduce danger, and mitigate points that can result in costly revisions. Design for meeting affects how designers choose components, select suppliers, and pcb assembly work with fabricators. Additionally, DfA drives decisions concerning PCB layouts. DfA rules contain making PCB design choices about performance, efficiency, and value, and each factor has a direct impression on the type, quality, and reliability of the accomplished product. The first goal of DfA is ease-of-meeting. Moving towards that objective requires an emphasis on eliminating complexity and lowering uncertainty. An emphasis on eliminating complexity pushes design groups to consider reducing the number of parts used for a PCB and to contemplate the kind of elements selected. For example, design groups may decide that choosing resistor or capacitor arrays-moderately than groups of single passive components-saves board space and lowers costs. The “back-to-basics” strategy to DfA also prompts design groups to consider-and perhaps rethink-the usage of fragile, heavy, or printed circuit board review bulky components. Heavy and bulky transformers, energy resistors, and mechanical assemblies drive delivery prices increased and require particular fabrication measures to make sure that the bodily design of the board helps the elements. Fabricators are assisted by the choice to reduce the variety of elements, as fewer elements mean that fabricators require less pick and place passes for their equipment. Using standardized, widespread elements also decreases the number of reel modifications for fabricator equipment. Although fabricators acknowledge that product design might require a particular part package deal, the use of distinctive packages can introduce delays in the manufacturing course of due to fabricator pcba necessities for comparing the PCB structure with datasheet footprints for every component. DfA requires attention to choices concerning the PCB layout. If you have any concerns regarding exactly where and how to use printed circuit board review, you can call us at our own webpage. Choosing to rely on vias-in-part pads or wire harness assemblies could initiate a ripple effect that impacts stability, time, and value. Because the reflow course of for through-in-part can enable tin to leak, fabricators take the extra time and cost to fill vias-in-element pads with epoxy. Rather than use wire harness assemblies that may increase costs and lead time, design teams should consider modular designs or completely different interconnection options. If a PCB board design stipulates wire bonding or conformal coatings, fabricators require mask drawings that present the areas designated for the finish or coating. An emphasis on standard parts eases concerns about the power of fabricators to procure components. Many EDA software program packages embrace element libraries that join the PCB design group with reliable manufacturers and recognized inventories. Modern EDA software program also improves the consistency and readability of Gerber files, assembly drawings, and Bill-of-Materials. This emphasis on consistency and clarity reduces time-to-market by guaranteeing fabricators that documentation includes all design revisions. The potential of EDA software to generate a BOM from the schematic. Reference notes also speeds the assembly course of. While fabricators continue to manually evaluation the BOM, the capability to remove incomplete, inaccurate, or lacking part numbers or mismatches between half numbers and descriptions saves time and reduces prices. PCB assembly concerns embody the choice of high quality elements, an excellent layout, and quality EDA software-discover the assets you want for all of this and more on the PCB Design and Analysis overview web page. The newest merchandise and options from OrCAD PCB Designer can assist you to obtain your subsequent great design. If you’re seeking to study extra about how Cadence has the answer for you, discuss to us and our staff of experts. Cadence PCB solutions is a complete entrance to back design tool to enable fast and efficient product creation. Cadence enables users precisely shorten design cycles to hand off to manufacturing via trendy, IPC-2581 trade commonplace.

A Quick Guide To Printed Circuit Assembly Documentation

The variety of digital devices that require printed circuit boards is rising at an exponential charge. User demand, increased performance, and lowering device size are driving a surge in demand for printed circuit boards. The global printed circuit board market is predicted to succeed in an estimated $72.6 billion by 2022. To fulfill increased demand for electronic devices, electronics manufacturers have superior their expertise, their materials, and their process to manufacture the printed circuit assembly rapidly and extra effectively. Whatever the advanced capability of electronic manufacturing service providers, almost every digital system would require functional parts to manage power, input/output interfaces, and processing. A printed circuit assembly (PCA) is the result of a course of to attach these useful digital parts with the wirings of printed circuit boards (PCB). Before these electronic components may be manufactured, customary documentation for a printed circuit meeting must be created. This text is a guide to printed circuit board meeting documentation that results in a reliable, repeatable, and price-effective PCA design. For the needs of this text, now we have assumed that the digital product design and electronic machine schematics are validated for objective and performance. While the electronic system schematics are being developed, a product designer will simultaneously develop the bill of fabric (BOM). The BOM is an inventory of the specific digital elements needed to complete the whole printed circuit assembly. While the electronic system schematics and bill of supplies are being developed, an electronic product designer can even develop the authorised vendor record (AVL). If you enjoyed this article and you would certainly like to receive more info pertaining to PCBA, studyroom.co.za, kindly go to our web site. The AVL adds extra element to the invoice of supplies by specifying an exact producer. Manufacturer’s part number for each electronic component line merchandise on the invoice of fabric. Whether a component is single-source or has a number of sources of provide is a essential consideration. An electronic product designer should make every effort to qualify alternate distributors on the AVL as early as possible. There might be notable repercussions to product price and supply if a single electronic part has limited sources or is just not accessible to the digital producer when needed. From a manufacturing perspective, the BOM and AVL will involve a excessive-stage of price and lead-time with respect to purchase and availability at PCA prototype, PCA manufacturing, and late-product lifecycle phases. It’s necessary that the electronic product designer considers digital materials value, lead-time, and anticipated longevity for each electronic part outlined within the PCA schematic capture and PCBA during the event of the PCA invoice of material. A printed circuit board (PCB) is a main part on the BOM. The PCB is the “canvas” or substrate that provides electrical connection. Mechanical support of all the other parts on the printed circuit meeting. The printed circuit board is a custom fabricated part important to the efficiency of the circuit. The design of printed circuit board and printed circuit assembly is a component art and half science. Training, expertise, and automated software suites are vital tools for the PCB designer. The technique of taking the schematic, BOM, and AVL by means of the PCB board format course of to a completed bodily state requires testing and validation. Software that guides a designer and utilizing “Design Rule Checking” software capabilities help contribute to a top quality base circuit, lowered manufacturing cycle occasions, and improved electronic product quality and reliability. An experienced PCB designer together with PCB software program can finally provide a extra value effective and repeatable production meeting. Once full the designer will present a printed circuit board assembly document package to the meeting workforce on the electronic manufacturing service supplier. While it is feasible for a PCA assembly team to quote and construct a printed circuit meeting with an abbreviated version of this PCA documentation bundle, it’s not beneficial. Detailed documentation for the printed circuit board and printed circuit board printed circuit meeting means a lower probability that an error can go from the design to the ultimate product. Troubleshooting is also less difficult when the PCA documentation. PCA bodily state becomes comparable “side by side”. The successful launch of a brand new digital machine is often contingent on the PCA documentation. To ensure the highest high quality, well timed production, and a cost-effective meeting, it is in one of the best curiosity of a PCA designer to complete a thorough documentation bundle for a printed circuit assembly.

While the electronic system schematics are being developed, a product designer will simultaneously develop the bill of fabric (BOM). The BOM is an inventory of the specific digital elements needed to complete the whole printed circuit assembly. While the electronic system schematics and bill of supplies are being developed, an electronic product designer can even develop the authorised vendor record (AVL). If you enjoyed this article and you would certainly like to receive more info pertaining to PCBA, studyroom.co.za, kindly go to our web site. The AVL adds extra element to the invoice of supplies by specifying an exact producer. Manufacturer’s part number for each electronic component line merchandise on the invoice of fabric. Whether a component is single-source or has a number of sources of provide is a essential consideration. An electronic product designer should make every effort to qualify alternate distributors on the AVL as early as possible. There might be notable repercussions to product price and supply if a single electronic part has limited sources or is just not accessible to the digital producer when needed. From a manufacturing perspective, the BOM and AVL will involve a excessive-stage of price and lead-time with respect to purchase and availability at PCA prototype, PCA manufacturing, and late-product lifecycle phases. It’s necessary that the electronic product designer considers digital materials value, lead-time, and anticipated longevity for each electronic part outlined within the PCA schematic capture and PCBA during the event of the PCA invoice of material. A printed circuit board (PCB) is a main part on the BOM. The PCB is the “canvas” or substrate that provides electrical connection. Mechanical support of all the other parts on the printed circuit meeting. The printed circuit board is a custom fabricated part important to the efficiency of the circuit. The design of printed circuit board and printed circuit assembly is a component art and half science. Training, expertise, and automated software suites are vital tools for the PCB designer. The technique of taking the schematic, BOM, and AVL by means of the PCB board format course of to a completed bodily state requires testing and validation. Software that guides a designer and utilizing “Design Rule Checking” software capabilities help contribute to a top quality base circuit, lowered manufacturing cycle occasions, and improved electronic product quality and reliability. An experienced PCB designer together with PCB software program can finally provide a extra value effective and repeatable production meeting. Once full the designer will present a printed circuit board assembly document package to the meeting workforce on the electronic manufacturing service supplier. While it is feasible for a PCA assembly team to quote and construct a printed circuit meeting with an abbreviated version of this PCA documentation bundle, it’s not beneficial. Detailed documentation for the printed circuit board and printed circuit board printed circuit meeting means a lower probability that an error can go from the design to the ultimate product. Troubleshooting is also less difficult when the PCA documentation. PCA bodily state becomes comparable “side by side”. The successful launch of a brand new digital machine is often contingent on the PCA documentation. To ensure the highest high quality, well timed production, and a cost-effective meeting, it is in one of the best curiosity of a PCA designer to complete a thorough documentation bundle for a printed circuit assembly.

PCB Assembly And Production Process – Comprehensive Guide

Printed Circuit Boards (PCBs) are electrical circuits created by laying printing tracks of a conductor such as copper on one or each sides of an insulating board. Printed circuit boards are used in all but the best electronic products. Mostly, PCBs are of composite materials, composite epoxy, and fiberglass. Loads of effort and time goes into the broad-scale assembly of PCBs and the method itself is particularly complicated. So, at this time we will take a deep dive into the steps involving PCB Assembly and pcba Production Process. PCB Assembly & Production Process or PCBA process, Is the means of soldering, assembling and arranging discrete elements onto a PCB board/Card. Back in the day, PCB assembly was handled by using solely soldering irons. But because the technology size is getting smaller & circuit complexity is rising with the passage of time, it became imperative to introduce automotive/ mechanize methods to increase production effectivity. So how exactly are these boards made? The PCB assembly course of consists of several automated and handbook steps. That can assist you higher perceive the PCBA Process, the following is a step by step information on PCB Assembly and Production Process. “I have been cooperating with PCBWay for a long time. I have solely constructive impressions. Printed circuit boards are at all times of excessive enough quality. Printed circuit boards are made very quickly, in addition to quickly delivered to Belarus. I selected this manufacturer as the primary supplier of printed circuit boards for my Easy-SDR undertaking. I did not regret this decision. I positively suggest this company for cooperation”. Prior to the addition of the elements to a board, solder paste must be fill into these areas of the board the place solder is in want. This process is just like display screen-printing a shirt. Usually, a fixture holds the PCB and solder stencil in place. An applicator then applies solder paste on the supposed areas in accurate quantities. The machine then spreads the paste across the stencil, PCBA applying it evenly to each open area. After eradicating the stencil, the solder paste remains within the set areas. During this a part of the meeting course of, the board with the solder paste goes by means of the choose and place process. The method begins by picking up a PCB board (https://www.misterpoll.com/) with a vacuum grip and moving it to the pick and place station. Then, a robot orients the PCB on the station and begins inserting elements on the PCB surface equivalent to discrete elements, surface mount parts or SMDs from a reel line of discrete parts. The parts remain in place by the floor tension of the solder paste which keeps them in place. Once the liquid solder paste and the parts all are in place, they undergo the reflow soldering course of. Here, the PCB Card moves by way of a large reflow oven, similar to a business heavy-obligation oven. This oven consists of a sequence of heaters which gradually heat the board to temperatures around 250°C or 480°F. This is hot enough to melt the solder in the solder paste. Once the solder has utterly melted. The PCB goes through a series of coolers, which solidify the solder paste. No PCBA course of is ever over with out thorough quality inspection. After soldering, the PCB card goes by way of a large variety of evaluation checks and inspections which includes handbook checks to look shorts and free connections, Optical Inspection to make sure solder well being between every connection on the PCB and PCB board X-ray inspection in case of multilayer PCBs. After quality assurance inspections, the PCB board goes via last purposeful testing. Here, the PCB is goes by way of various phases, with the intention to simulate the circumstances in which it should operate outdoors the manufacturing facility. It is important to test PCB Cards earlier than they depart the manufacturing unit to make sure buyer satisfaction. So, in conclusion, PCBA process revolves across the above given steps. Using these steps, PCB Manufacturers ensure the quality of their PCB boards.