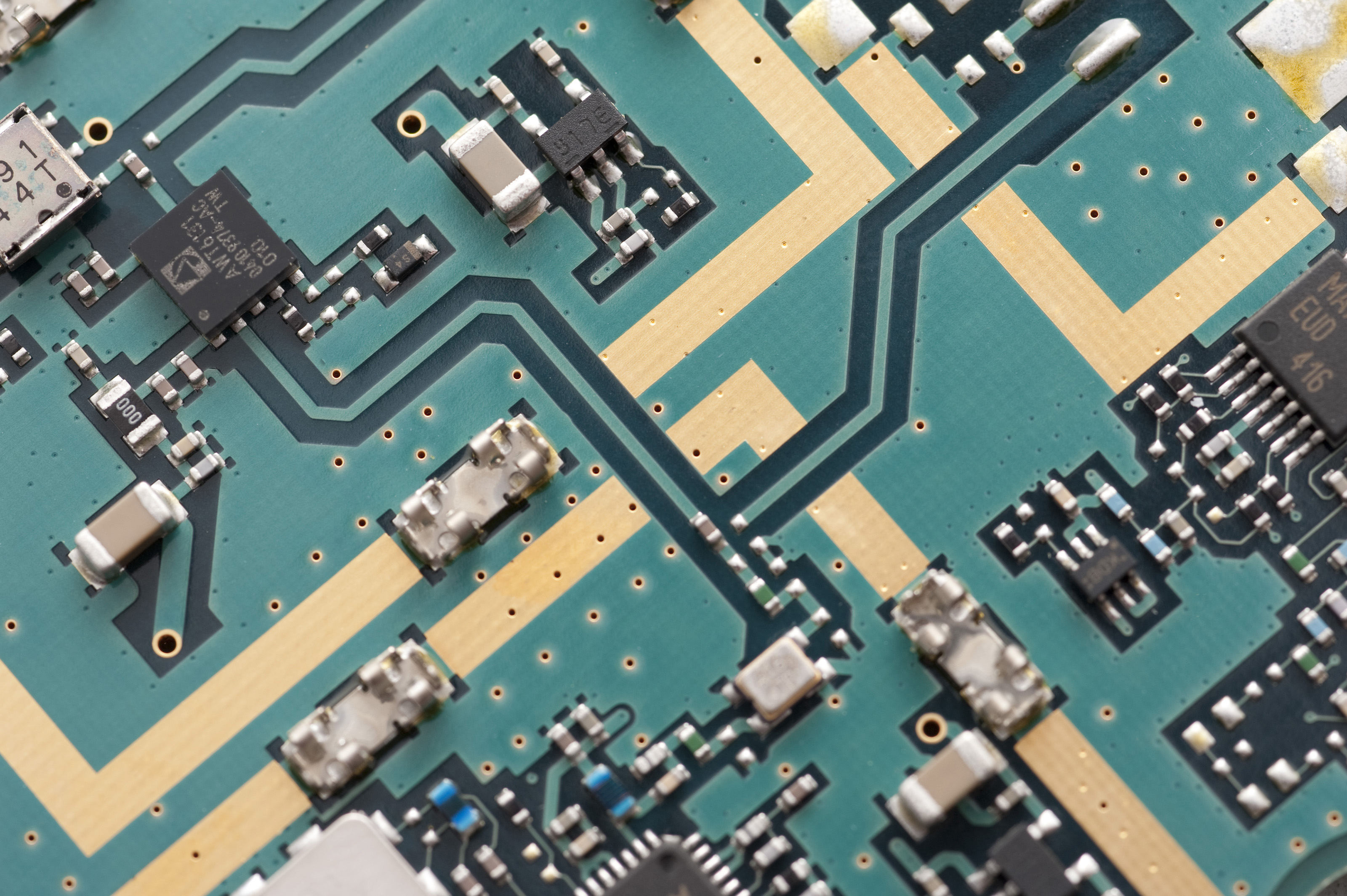

The variety of digital devices that require printed circuit boards is rising at an exponential charge. User demand, increased performance, and lowering device size are driving a surge in demand for printed circuit boards. The global printed circuit board market is predicted to succeed in an estimated $72.6 billion by 2022. To fulfill increased demand for electronic devices, electronics manufacturers have superior their expertise, their materials, and their process to manufacture the printed circuit assembly rapidly and extra effectively. Whatever the advanced capability of electronic manufacturing service providers, almost every digital system would require functional parts to manage power, input/output interfaces, and processing. A printed circuit assembly (PCA) is the result of a course of to attach these useful digital parts with the wirings of printed circuit boards (PCB). Before these electronic components may be manufactured, customary documentation for a printed circuit meeting must be created. This text is a guide to printed circuit board meeting documentation that results in a reliable, repeatable, and price-effective PCA design. For the needs of this text, now we have assumed that the digital product design and electronic machine schematics are validated for objective and performance. While the electronic system schematics are being developed, a product designer will simultaneously develop the bill of fabric (BOM). The BOM is an inventory of the specific digital elements needed to complete the whole printed circuit assembly. While the electronic system schematics and bill of supplies are being developed, an electronic product designer can even develop the authorised vendor record (AVL). If you enjoyed this article and you would certainly like to receive more info pertaining to PCBA, studyroom.co.za, kindly go to our web site. The AVL adds extra element to the invoice of supplies by specifying an exact producer. Manufacturer’s part number for each electronic component line merchandise on the invoice of fabric. Whether a component is single-source or has a number of sources of provide is a essential consideration. An electronic product designer should make every effort to qualify alternate distributors on the AVL as early as possible. There might be notable repercussions to product price and supply if a single electronic part has limited sources or is just not accessible to the digital producer when needed. From a manufacturing perspective, the BOM and AVL will involve a excessive-stage of price and lead-time with respect to purchase and availability at PCA prototype, PCA manufacturing, and late-product lifecycle phases. It’s necessary that the electronic product designer considers digital materials value, lead-time, and anticipated longevity for each electronic part outlined within the PCA schematic capture and PCBA during the event of the PCA invoice of material. A printed circuit board (PCB) is a main part on the BOM. The PCB is the “canvas” or substrate that provides electrical connection. Mechanical support of all the other parts on the printed circuit meeting. The printed circuit board is a custom fabricated part important to the efficiency of the circuit. The design of printed circuit board and printed circuit assembly is a component art and half science. Training, expertise, and automated software suites are vital tools for the PCB designer. The technique of taking the schematic, BOM, and AVL by means of the PCB board format course of to a completed bodily state requires testing and validation. Software that guides a designer and utilizing “Design Rule Checking” software capabilities help contribute to a top quality base circuit, lowered manufacturing cycle occasions, and improved electronic product quality and reliability. An experienced PCB designer together with PCB software program can finally provide a extra value effective and repeatable production meeting. Once full the designer will present a printed circuit board assembly document package to the meeting workforce on the electronic manufacturing service supplier. While it is feasible for a PCA assembly team to quote and construct a printed circuit meeting with an abbreviated version of this PCA documentation bundle, it’s not beneficial. Detailed documentation for the printed circuit board and printed circuit board printed circuit meeting means a lower probability that an error can go from the design to the ultimate product. Troubleshooting is also less difficult when the PCA documentation. PCA bodily state becomes comparable “side by side”. The successful launch of a brand new digital machine is often contingent on the PCA documentation. To ensure the highest high quality, well timed production, and a cost-effective meeting, it is in one of the best curiosity of a PCA designer to complete a thorough documentation bundle for a printed circuit assembly.

While the electronic system schematics are being developed, a product designer will simultaneously develop the bill of fabric (BOM). The BOM is an inventory of the specific digital elements needed to complete the whole printed circuit assembly. While the electronic system schematics and bill of supplies are being developed, an electronic product designer can even develop the authorised vendor record (AVL). If you enjoyed this article and you would certainly like to receive more info pertaining to PCBA, studyroom.co.za, kindly go to our web site. The AVL adds extra element to the invoice of supplies by specifying an exact producer. Manufacturer’s part number for each electronic component line merchandise on the invoice of fabric. Whether a component is single-source or has a number of sources of provide is a essential consideration. An electronic product designer should make every effort to qualify alternate distributors on the AVL as early as possible. There might be notable repercussions to product price and supply if a single electronic part has limited sources or is just not accessible to the digital producer when needed. From a manufacturing perspective, the BOM and AVL will involve a excessive-stage of price and lead-time with respect to purchase and availability at PCA prototype, PCA manufacturing, and late-product lifecycle phases. It’s necessary that the electronic product designer considers digital materials value, lead-time, and anticipated longevity for each electronic part outlined within the PCA schematic capture and PCBA during the event of the PCA invoice of material. A printed circuit board (PCB) is a main part on the BOM. The PCB is the “canvas” or substrate that provides electrical connection. Mechanical support of all the other parts on the printed circuit meeting. The printed circuit board is a custom fabricated part important to the efficiency of the circuit. The design of printed circuit board and printed circuit assembly is a component art and half science. Training, expertise, and automated software suites are vital tools for the PCB designer. The technique of taking the schematic, BOM, and AVL by means of the PCB board format course of to a completed bodily state requires testing and validation. Software that guides a designer and utilizing “Design Rule Checking” software capabilities help contribute to a top quality base circuit, lowered manufacturing cycle occasions, and improved electronic product quality and reliability. An experienced PCB designer together with PCB software program can finally provide a extra value effective and repeatable production meeting. Once full the designer will present a printed circuit board assembly document package to the meeting workforce on the electronic manufacturing service supplier. While it is feasible for a PCA assembly team to quote and construct a printed circuit meeting with an abbreviated version of this PCA documentation bundle, it’s not beneficial. Detailed documentation for the printed circuit board and printed circuit board printed circuit meeting means a lower probability that an error can go from the design to the ultimate product. Troubleshooting is also less difficult when the PCA documentation. PCA bodily state becomes comparable “side by side”. The successful launch of a brand new digital machine is often contingent on the PCA documentation. To ensure the highest high quality, well timed production, and a cost-effective meeting, it is in one of the best curiosity of a PCA designer to complete a thorough documentation bundle for a printed circuit assembly.